What is Stair?

The means of communication between various floors is offered by various structures such as

stairs, lifts, ramps, ladders, escalators.

STAIR:

building. Stairs are designed to provide an easy and quick access to different floors.

• A staircase is an enclosure which contains the complete stairway.

• In a residential house stairs may be provided near the entrance.

• In a public building, stairs must be from main entrance and located centrally.

STAIRCASE: Room of a building where stair is located.

STAIRWAY: Space occupied by the stair.

TECHNICAL TERMS

1. BALUSTER: Vertical member which is fixed between stairway and horizontal to

provide support to hand rail.

2. BALUSTRADE: Combined framework of baluster and hand rail.

3. STRING: Inclined member of a stair which supports ends of steps. They are of two

types, (i) cut/open string, (ii) closed/housed string.

• In open string, upper edge is cut away to receive the ends of steps.

• In closed string, the ends of steps are layed between straight and parallel edges of

the string.

4. FLIGHT : Unbroken series of steps between the landings.

5. GOING: horizontal distance between faces of two consecutive risers.

6. HANDRAIL: inclined rail over the string. Generally it is moulded. It serves as a guard

rail. It is provided at a convenient height so as to give grasp to hand during ascent and

descent.

7. HEAD ROOM: vertical distance between nosingsof one flight and the bottom of flight

immediately above is called head room.

8. LANDING: horizontal platform between two flights of a stair. A landing facilitates

change of direction and provides an opportunity to take rest.

9. NEWEL POST: vertical member placed at ends of flights to connect ends of string and

hand rail.

10. NOSING: projection part of tread beyond face of riser.

11. LINE OF NOSING: imaginary line parallel to strings and tangential to nosings. The

underface of hand rail should coincide with line of nosing.

12. PITCH: angle of inclination of stair with floor.

Angle of inclination of line of nosing with horizontal.

13. RISE: vertical distance between two successive treads.

14. RISER: vertical member of the step, which is connected to treads.

15. RUN: length of a stair in a horizontal plane which includes length of landing.

16. SCOTIA: an additional finish provided to nosing to improve the elevation of the step

which also provides strength to nosing.

17. SOFFIT: under surface of a stair. Generally it is covered with ceiling or finished with

plaster.

18. STEP: combination of trade and riser. Different types are.

• Commode steps: it has curved riser and tread

• Dancing step: they don’t radiate from a common centre

• Flier: ordinary step of rectangular shape in plan

• Round ended step: similar to bullnose step except that its ends are semicircular

in plan

• Splayed step: it has either one end/both ends splayed in plan

• Winder : this is a tapering step and is used to change the direction of a

flight. The winders radiate from a common centre.

• Tread: horizontal upper portion of a step.

• Waist: thickness of structural slab in RCC stair

• Carriage: a rough timber supporting steps of wooden stairs

REQUIREMENT OF GOOD STAIRCASE

• Stairs should be so located that it is easily accessible from the different rooms of a

building.

• It should have adequate light and proper ventilation.

• It should have sufficient stair width to accommodate no. of persons in peak

hour/emergency.

Generally for interior stairs, clear width may be

at least 50cm in one/two family dwellings

at least 90cm in hotels, motels, apartment and industrial building

at least 1.1m for other types like hospitals, temples etc.

• No. of steps in a flight should be restricted to a maximum of 12, minimum of 3.

• Ample head room should be provided for tall people to give feeling of spaciousness. It

should be minimum of 2.15m.

• Risers and treads sizes should be provided from common point view.

Tread = 2.5cm – 32.5 cm (wide), excluding nosing.

Tread < 25cm, should have a nosing of about 2.5cm

Comfortable height of riser = 17.5cm-18.5cm.

Riser * tread = (400-410). 426

Riser + tread = (42.5-43.5) 40-45

2(riser) + tread = 60-64 cm 60

Take rise = 14cm, going = 30cm.for each 2cm substracted from going, add

1cm to rise.

• Stair width depends on purpose and importance of building.

• No. of stairways required should be controlled by maximum floor area contributory to

stairway.

(No. of persons using stairs/floor/55cm stairwidth)

should be 15 for hospital and nursing home.

Should be 30 for institutional and residential building

Should be 45 for storage building

Should be 60 for mercantile, educational, industrial building, theatres, restaurants.

Should be 80 for church concert hall, museum

Should be 320 for stadium and amutementstructures.

• Minimum width of landing = width of stair

• Maximum and minimum pitch should be 400 and 250.

• Winder should be provided at lower end of flight when it is essential. Use of winder

should be avoided.

• Live load to be considers n stairs have been stipulated by IS 875-1964

• Stairs and landings should be designed for live load of 3000kg/m.s2 in building where

there are no possibilities of overcrowding in public building and warehouses where

overcrowding is likely live load may be taken as 500kg

• Railing should be design for horizontal force of 55 and vertical force of 70

applied at top of rail

TYPES OF STAIRS

1. Straight stair:

Here there is no change in the direction of any flight between two successive

floors. It can be straight run with a single flight between floors or a series of flights

without change indirection

Parallel stairs

Angle stairs

Scissors stair

Straight stair can have a change in direction at any intermediate landing.

In parallel stair, there is complete reversal of direction occurs.

In angle stair, successive flights are at an angle to each other.

Scissor stairs are comprised of a pair of straight runs in opposite direction and are

placed on opposite sides of a fire resistive wall.

2. Turning stairs:

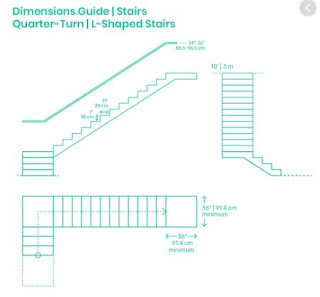

• Quarter turn stair :

Provided where flight direction is to be changed by 900

Change in direction can be affected by either introducing a quarter

space landing or by providing winders at junctions.

• Half turn stair:

They change their direction through 1800. They can be dog legged and

open newel.

In doglegged stair, flights are in opposite direction and no space is

provided between the flights.

In open newel stair, there is a well/opening between flights and may be

used to accommodate lift.

Open newel stairs are used at places where sufficient space is

available.

• Three quarter turn stair:

They change in the direction through 2700 or direction is changed with

its upper flight crossing the bottom one.

In this type an open well is formed.

3. Circular stair:

When viewed from above, appear to follow a circle with a single centre of

curvature and large radius.

Generally they are provided at the rear of a building to the access for serving

at various floors.

All the steps radiate from a newel post in the form of winders.

Made up of stone,cast iron/RCC.

4. Spiral stairs:

Similar to previous one except that the radius of curvature is small and the

stair may be supported by a centre post.

Over all diameter range from 1-2.5m

5. Curved stair:

When view from above appear to follow a curve with 2 or more centre of

curvature, such as ellipse.

6. Geometric stair:

They have no newel post are of any geometric shape.

The change in direction is achieved through winders.

They needs more skills for its construction and are weaker than open newel

stairs

Here the open well between forward and backward flights is curved.

7. Bifurcated stair:

So arranged that there is a wide at the start and subdivided into narrow flights

at mid landing.

The two narrow flights start from either side of mid landing.

They are suitable for modern public buildings.

CLASSIFICATION OF STAIRS BASED ON MATERIALS OF CONSTRUCTION

General materials used in construction of stairs are

o Wooden

o Stone

o Brick

o Metals/steel

o Plane concrete

o RCC

• Wooden stair

o As they are light in weight, mostly used for residential building.

o The main objection to this stair is that it is easily attacked by fire and

thus, in fire, the occupants of upper floor can’t escape.

o If it is made from good timber like Teak, and thickness is about 45mm,

it becomes sufficiently fire proof and allows enough time for occupants

on upper floor to escape.

Factors to be considered here are,

The string supporting ends of wooden steps may be a cut

string/closed string.

Scotia blocks may be provided to give additional finish to

wooden steps.

Small triangular wooden blocks called glue blocks may be

provided at inner angle formed between a trade and riser, to

provide additional strength.

A metal strip may be provided on nosing of wooden step to

increase its resistance against wear and tear.

The landing may be formed by providing wooden beams of

suitable sizes.

Sometimes risers are omitted. trades are housed in strings and

soffit is covered with wooden battens/metal sheets.

The timber used should be free from fungal decay, insect

attack, or any defect. Edges may be finished smooth and excess

light timber should not be used.

• Metal Stair

o They are not frequently/commonly used stairs.

o The external fireescape stairs are generally made of metal.

o Common metals are CI, bronze, and mild steel.

o Widely used in factories, workshop, and godowns.

Main features are,

Stringers are usually of channel section

Tread and riser of a step may be of one unit or may not

be

Tread and risers are supported on angles, which are

connected to stringers.

Risers may be totally omitted.

Spirals stairs of CI consists of CI newel fixed in center

around which the CI steps are fixed.

For metal stairs metal balusters with pipe handrail are

used.

• RCC Stair

o Commonly used in all type of construction.

o They resist better fire and wear than any other material and

can be moulded to desired shape.

o The step can be provided with suitable finishing material such

as marble, terrazzo, tiles etc.

o They can be easily maintained, strong, durable and pleasing in

appearance.

o They can be designed for greater widths and layer spans.

o The steps may cast in situ/pre cast.

o It is possible to pre cast a flight and place it in position by

equipments.

The materials can be used together/combination with each other to form

COMPOSITE STAIRS.

Read More:

What is Cement? What are the types of cement and their uses?

Composition of Cement clinker and Hydration of Cement

Types of Tests on Cement to Check the Quality

PPC or OPC And Their Difference

All Types of Cement in Construction

Must-Know Points to Check on a Cement Bag Before Buying It

Production of concrete, Batching, Mixing, Compaction and Curing

No comments:

Post a Comment

If you are getting more information from civilengineerfriend page please give your comments. Share the page information in your whatsapp group. Subscribe our page to get more information.