WHAT IS CAVITY WALL

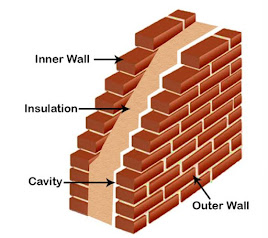

A cavity wall or hollow wall is the one which consists of two separate walls called leader or

skins with a cavity or gap in between them.

The two leaves of a cavity wall may be of equal thickness if it is a non load bearing.

The internal leaf may be thicker than the external leaf to meet the structural

requirements.

Cavity walls are often constructed forgiving better thermal insulation to the building.

It also prevents the dampness to enter and act as sound insulation.

The inner and outer skins should not be less than 10cm each(half brick).

ADVANTAGES :-

There is no direct contact between the inner and outer leaves of the wall (except at wall ties).

Hence moister (dampness) can not travel inside the building.

The cavity between the two leaves is full of air which is bad conductor of heat. hence

transmission of heat from external face to the inside the room is very much reduced.

Cavity wall have about 25% greater insulating value than the solid walls.

Cavity walls also offer good insulation against sound.

The nuisanceof efflorescence is also very much reduced.

They are cheap and economical .

Loads and foundation are reducedbecause offission solid.

GENERAL FEATURES OF CAVITY WALLS:-

In case of brick cavity wall ,each is half brick thick .such wall is capable of taking load

of two storyedof the domestic type , if heavier loads are to be supported ,the thickness of

inner leaf can be increased .

The cavity wall should neither be less then 40mm more for more than 100mm in

width .

The inner and outer skins are adequately tied together by means of the special walls

ties placed in suitable arrangement , at the rate of at least ties to a square meter of

wall area .

The ties are staggered .ties must be placed at 300mm vertical intervals at all angles

and doors and windows jambs to increase stability .

Since the cavity separates the two leaves of the wall, to prevent moisture to enter , it

is essential to provide a vertical damp proof course at window and door reveals .

The damp proof course should be flexible.

PORPOSE FOR PROVIDING A CAVITY WALL:-

1.PREVENTATION OF DAMPNESS:-When cavity wall construction is adopted there is

considerable decrease in the prevention of dampness from outside to inside of the building.

2.HEAT INSULATION:-The air in the cavity acts as a non-conductor of heat and hence the

uniform temperature is maintained inside the building.

3.SOUND INSULATION:- The considerable portion of external noise is not allowed to enter

inside the building by adopting cavity wall construction.

4.LOAD ON FOUNDATION:-Due to less solid thickness of wall the loads on foundation are

considerably reduced.

5. EFFLORESCENCE:-The construction of cavity wall results in the reduction of nuisance of

efflorescence to a great extent.

6.ECONOMICAL:-In addition to above mentioned advantages, it is found that the

construction cost of a cavity wall is 20% less than the construction cost of a corresponding

solid wall .

CONSTRUCTION DETAILS OF CAVITY WALL:-

A cavity wall is constructed of two leaves that is inner and outer with a hollow space in

between them.

The width of cavity varies from 50mm to 100mm and it stands vertically. The outer is

generally of ½ brick thickness and the inner wall may be of ½ of 1 brick thickness.

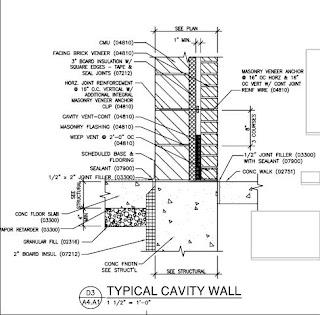

The two portions of the wall are connected by means of metal ties or specially prepared

bonded bricks. The metal ties are generally of wrought iron or mild steel and they are coated

with tar or galvanizedso as to have protection against rust.

Where corrosion is heavy, the metal ties of copper or bronze may be adopted. The metal ties

are placed at a horizontal distance of 900 mm and a vertical distance of 450 mm. The

arrangement of ties is kept staggered .

The outer wall is generally constructed in stretcher bond , but it may be constructed in the

flemish bond or english garden-wall bond or flemish garden-wall bond by using bats for

headers.

As far as possible, there should be no intimate contact between two leaves of the cavity wall.

Construction at base:-

The cavity may be started from the top of foundation concrete& the hollow space, up to a

level of about 100mm to 300mm below the damp-proofing course at plinth level, may be

filled with plain cement concrete of proportion 1:2:4.

But, as the cavity below damp-proof course does not serve any purpose ,the brickwork up to a

level of 100mm to 300mm below the damp-proofing course at plinth level may be

constructed solidly.

The increased thickness of wall will also be helpful in supporting the load to be carried by the

wall.

Construction at opening:-

In the plan, the cavity is discontinued at the opening such as doors, windows, etc. The jambs

of openings for doors and windows are constructed solid either in brickwork or with layers of

slates or tiles.

If metal windows are provided, specially prepared metal frames can be used for this purpose.

An inclined flexible D.P.C is provided to act as a bridge over the cavity. the D.P.C should be

extend lengthwise beyond the frame for a distance of about 150mm on either side.

Construction at top:-

It is necessary to take adequate steps at top to prevent the entry of dampness to the inside

portion of the wall.

The cavity may be constructed up to the coping of the parapet wall or alternatively it may be

closed at the bottom of the parapet wall by a damp proofing course.

In case of a pitched roof, the tops of two portions are connected by solid brickwork to support

the roof truss and damp-proofing course is inserted immediately below this solid portion.

Ventilation:-

It is necessary to provide enough ventilation to the hollow space of the cavity wall. This is

achieved by providing openings at top at bottom of the wall so that a free current of air is

established. The openings are to be fitted with gratings so that entry of rats and other

varmintsto the hollow space is prevented. Sometimes, the air bricks are used for this purpose.

Shape and slope of ties:-

The metal ties which are used to connect the outer and inner portions should be so shaped and

placed that water from outer portion does not pass along inner portions. They should thus be

sloped away from the inner portion.

Dropping of mortar, bats etc.:-

During construction of a cavity wall, it should be seen that mortar , bats, etc., do not fall in

the hollow space. The presence of such material in the hollow space seriously affects the

working of a cavity wall. For this purpose, a wooden strip of width slightly less than that of

the hollow space, is supported on ties and it is raised as the work proceeds. Also, some bricks

at the bottom are left out and bats, etc. Falling in the cavity are removed from these holes.

When the work is completed, this bottom portion is sealed by filling it with bricks. It also be

seen that the vermins or mosquitoes do not find access in the cavity.

Design:-

The outside portion of a cavity wall should be treated only as a protecting skin and not as a

member of a load bearing wall. The inside portion should have sufficient thickness to carry

safely the load coming on it.

Read More:

What is Cement? What are the types of cement and their uses?

Composition of Cement clinker and Hydration of Cement

Types of Tests on Cement to Check the Quality

PPC or OPC And Their Difference

All Types of Cement in Construction

Must-Know Points to Check on a Cement Bag Before Buying It

Production of concrete, Batching, Mixing, Compaction and Curing

No comments:

Post a Comment

If you are getting more information from civilengineerfriend page please give your comments. Share the page information in your whatsapp group. Subscribe our page to get more information.