Types of Tests on Cement to Check the Quality

- Fineness Test

- Consistency Test

- Setting Time Test

- Strength Test

- Soundness Test

- Heat of Hydration Test

- Tensile Strength Test

- Chemical Composition Test

Various

tests on cement:

Basically two types of tests are under taken for assessing

the quality of cement. These are either field test or lab tests. The current

section describes these tests in details.

Field test:

There are four field tests may be carried out to as certain

roughly the quality of cement.There are four types of field tests to access the

colour, physical property, and strength of the cement as described below.

Colour

The colour of cement should be uniform.

• It

should be typical cement colour i.e. grey colour with a light greenish shade.

Physical properties

• Cement

should feel smooth when touched between fingers.

• If

hand is inserted in a bag or heap of cement,it should feel cool.

Presence of lumps

• Cement

should be free from lumps.

• For

a moisture content of about 5 to 8%,this increase of volume may be much as 20

to 40 %,depending upon the grading of sand.

Strength

• A

thick paste of cement with water is made on a piece of thick glass and it is

kept under water for 24 hours.It should set and not crack.

Laboratory tests:

Six laboratory tests are conducted mainly for assessing the

quality of cement. These are:

fineness, compressive strength, consistency, setting time, soundness and tensile

strength.

Fineness Test

• This

test is carried out to check proper grinding of cement.

• The

fineness of cement particles may be determined either by sieve test or

permeability apparatus test.

• In

sieve test ,the cement weighing 100 gm is taken and it is continuously passed

for 15 minutes through standard BIS sieve no. 9.The residue is then weighed and

this weight should not be more than 10% of original weight.

• In

permeability apparatus test,specific area of cement particles is

calculated.This test is better than sieve test.The specific surface acts as a

measure of the frequency of particles of average

size.

● Fineness test for cement formula is (W2/W1)×100

Fineness test for cement formula = (W2/W1)×100, where, W2 = Cement residue on sieve, W1 = Weight of given sample of cement.

Then after, calculate the percentage of Weight of cement-retained on Sieve.

Repeat this procedure with three different samples of cement and average the values for accurate results.

● Test Result 1 for sample: Let W1 = 100g, W2= 4.68, then fineness = (W2/W1)×100 = (4.68/100)×100 = 4.48%

● Test Result 2 for sample: Let W1 = 100g, W2= 6.28, then fineness = (W2/W1)×100 = (6.28/100)×100 = 6.28%

● Test Result 3 for sample: Let W1 = 100g, W2= 7.64, then fineness = (W2/W1)×100 = (7.64/100)×100 = 7.64%

Now average = (4.48%+6.28%+7.64%)/3= 6.14%, so Fineness value for given sample of cement is 6.14%.

The standard cement should have fineness less than 10 % as per IS Recommendations.

The purpose of this test is to determine the percentage of water required for preparing cement pastes for other tests.

• Take 300 gm of cement and add 30 percent by weight or 90 gm of water to it.

• Mix water and cement thoroughly.

• Fill the mould of Vicat apparatus and the gauging time should be 3.75 to 4.25 minutes.

• Vicat apparatus consists of aneedle is attached a movable rod with an indicator attached to it.

• There are three attachments: square needle,plungerand needle with annular collar.

• The plunger is attached to the movable rod.the plunger is gently lowered on the paste in the mould.

• The settlement of plunger is noted.If the penetration is between 5 mm to 7 mm from the bottom of mould,the water added is correct.If not process is repeated with different percentages of water till the desired penetration is obtained.

Setting time Test

• This test is used to detect the deterioration of cement due to storage.The test is performed to find out initial setting time and final setting time.

• Cement mixed with water and cement paste is filled in the Vicat mould.

• Square needle is attached to moving rod of vicat apparatus.

• The needle is quickly released and it is allowed to penetrate the cement paste.In the beginningthe needle penetrates completely.The procedure is repeated at regular intervals till the needle does not penetrate completely.(upto 5mm from bottom)

• Initial setting time =<30min for ordinary Portland cement and 60 min for low heat cement.

• The cement paste is prepared as above and it is filled in the Vicat mould.

• The needle with annular collar is attached to the moving rod of the Vicat apparatus.

• The needle is gently released. The time at which the needle makes an impression on test block and the collar fails to do so is noted.

• Final setting time is the difference between the time at which water was added to cement and time as recorded in previous step,and it is =<10hours.

Compressive strength

• This

test is carried out to determine the compressive strength of cement.

• The

mortar of cement and sand is prepared in ratio 1:3.

• Water

is added to mortar in water cement ratio 0.4.

• The

mortar is placed in moulds.The test specimens are in the form of cubes and the

moulds are of metals.For 70.6 mm and 76 mm cubes ,the cement required is 185gm

and 235 gm respectively.

• Then

the mortar is compacted in vibrating machine for 2 minutes and the moulds are

placed in a damp cabin for 24 hours.

• The

specimens are removed from the moulds and they are submerged in clean water for

curing.

• The cubes are then tested in compression testing machine at the end of 3days and 7 days. Thus compressive strength was found out.

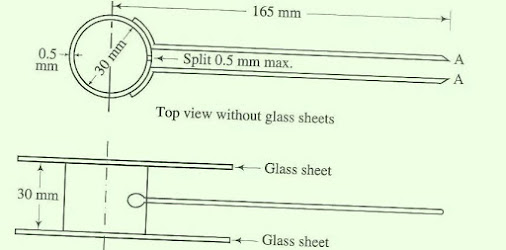

Soundness Test

• The

purpose of this test is to detect the presence of uncombined lime in the

cement.

• The

cement paste is prepared.

• The

mould is placed and it is filled by cement paste.

• It

is covered at top by another glass plate.A small weight is placed at top and

the whole assembly is submerged in water for 24 hours.

• The

distance between the points of indicator is noted.The mould is again placed in

water and heat is applied in such a way that boiling point of water is reached

in about 30 minutes. The boiling of water is continued for one hour.

• The

mould is removed from water and it is allowed to cool down.

The distance between the points of indicator is again measured.The difference between the two readings indicates the expansion of cement and it should not exceed 10 mm.

Heat of Hydration Test

During the hydration of cement, heat is produced due to chemical reactions. This heat may raise the temperature of concrete to a high temperature of 50°C. To avoid these, in large scale constructions low-heat cement has to be used.

Tensile strength

• This

test was formerly used to have an indirect indication of compressive strength

of cement.

• The

mortar of sand and cement is prepared.

• The

water is added to the mortar.

• The

mortar is placed in briquette moulds.The mould is filled with mortar and then a

small heap of mortar is formed at its top.It is beaten down by a standard

spatula till water appears on the surface.Same procedure is repeated for the

other face of briquette.

• The

briquettes are kept in a damp for 24 hours and carefully removed from the

moulds.

• The briquettes are tested in a testing machine at the end of 3 and 7 days and average is found out.

Chemical Composition Test

Different tests are conducted to determine the amount of various constituents of cement. The requirements are based on IS: 269-1998, is as follows:

- The ratio of the percentage of alumina to that of iron oxide should not be less than 0.66.

- Lime Saturation Factor (LSF), i.e., the ratio of the percentage to that of alumina, iron oxide and silica should not be less than 0.66 and not be greater than 1.02.

- Total loss on ignition should not be greater than 4%.

- Total sulphur content should not be greater than 2.75%.

- Weight of insoluble residue should not be greater than 1.50%.

- Weight of magnesia should not be greater than 5%.

Read More:

What is Cement? What are the types of cement and their uses?

Composition of Cement clinker and Hydration of Cement

Types of Tests on Cement to Check the Quality

PPC or OPC And Their Difference

No comments:

Post a Comment

If you are getting more information from civilengineerfriend page please give your comments. Share the page information in your whatsapp group. Subscribe our page to get more information.