Curing period:

For ordinary Portland cement, the curing period is about 7 days to 14 days.If rapid hardening

cement is used the curing period can be considerably reduced.

Disadvantages of improper curing:

Following are the disadvantages of improper curing of concrete:

The chances of ingress of chlorides and atmospheric chemicals are very high.The

compressive and flexural strengths are lowered.The cracks are developed due to plastic

shrinkage, drying shrinkage and thermal effects.The durability decreases due to higher

permeability.The frost and weathering resistances are decreased.The rate of carbonation

increases.The surfaces are coated with sand and dust and it leads to lower the abrasion

resistance.The disadvantages are more prominent in those parts of surfaces which are directly

exposed or which have large surfaces compared to depth such as roads, canal, bridges,

cooling towers, chimneys etc.

Factors affecting evaporation of water from concrete:

The evaporation of water depends upon the following 4 factors: Air temperature, Fresh

concrete temperature, Relative humidity and Wind velocity.

From the above mentioned factors it can be concluded environment directly influences the

process of evaporation, hence only the fresh concrete temperature can be monitored or

supervised by the concrete technologists.The evaporation of water in the first few hours can

leave very low amount of water in the concrete hydration, this leads to various shrinkage

cracks.Under normal condition the average loss of water varies from 2.5 to 10 N per m2 per

hour.The major loss occurs in the top 50 mm layer over a period of 3 hours, the loss could be

about 5% of the total volume of that layer.

Methods of curing:

While selecting any mode of curing the following two factors are considered:

• The loss of water should be prevented.

• The temperature should be kept minimum for dissipation of heat of hydration.

Methods of curing can be categorised into the following categories:

Water curing-preventing the moisture loss from the concrete surface by continuously wetting

the exposed surface of concrete.

Membrane curing-minimizing moisture loss from concrete surface by covering it with an

impermeable membrane.

Steam curing-keeping the surface moist and raising the temperature of concrete to accelerate

the rate of strength gain.

Water curing is of the following types:

Ponding:

most inexpensive and common method of curing flat slabs, roofs, pavements etc. A

dike around the edge of the slab, is erected and water is filled to create a shallow pond. Care

must be taken to ensure that the water in the pond does not dry up, as it may lead to an

alternate drying and wetting condition.

Sprinkling:

fogging and mist curing- using a fine spray or fog or moist of water to the

concrete can be efficient method of supplying water to concrete during hot weather, which

helps to reduce the temperature of concrete.

Wet coverings:

water absorbent fabrics may be used to maintain water on concrete surfaces.

They must be continuously kept moist so as to prevent the fabrics from absorbing water from

the body of concrete,due to capillary action.

Impermeable membrane curing is of following types:-

Formwork:

leaving the form work in place during the early age of concrete is an efficient

method of curing.

Plastic sheeting:

plastic sheets form an effective barrier to control the moisture losses from

the surface of concrete, provided they are secured properly and protected from damage. The

efficiency of this system can be enhanced by flooding the concrete surface with water, under

the plastic sheet.

Membrane curing compounds:

Curing compounds are wax, acrylic and water based liquids

are spread over the freshly finished concrete to form an impermeable membrane that

minimises the loss of moisture from the concrete surfaces.These are cost effective methods of

curing where standard curing procedures are difficult to adopt.When applied to cure concrete

the time of the application is critical for maximum effectiveness.Too early application dilutes

the membrane, whereas too late application results in being absorbed into the concrete.They

must be applied when the free water on the surface has evaporated.For concrete with low w/c

ratio, this is not a suitable process.

Steam curing:

Steam curing is the process of accelerating the early hardening of concrete and

mortars by exposing it to steam and humidity. These types of curing systems are adopted for

railway sleepers, concrete blocks, pipes, manhole covers, poles etc.Precast iron is cured by

this method under pressure.Curing in hot and cold weather requires additional attention.

Hot weather:

During hot weather, concrete must be protected from excessive drying and

from direct wind and sun. Curing materials which reflect sunlight to reduce concrete

temperature must be used.

Cold weather: Some problems associated with temperature below 400C are:

• Freezing of concrete before strength is developed.

• Slow development of concrete strength.

• Thermal stresses induced by the cooling of warm concrete to cooler ambient

temperatures

Chemical curing: In this method water is sprinkled over the surface, after adding certain

amount of some hygroscopic material (e.g. sodium chloride or calcium chloride). The

hygroscopic materials absorb moisture from the atmosphere and thus keep the surface damp.

Alternating current curing: Concrete can be cured by passing alternating current through

freshly laid concrete.

Water cement ratio and compressive strength

A cement of average composition requires about 25% of water by mass for chemical reaction.

In addition, an amount of water is needed to fill the gel pores. Nearly 100 years ago, Duff

Abrams discovered the direct relationship between water-to-cement ratio and strength,

i.e.,lesser the water used higher the strength of the concrete,since too much water leaves lots

of poresin the cement past. According toAbram’s law, the strength of fully compacted

concrete at a given age and normal temperature is inversely proportional to the water –

cement ratio. Here the water-cement ratio is the relative weight of water to the cement in the

mixture. For most applications, water-to-cement ratio should be between 0.4 and 0.5 lower

for lower permeability and higher strength. In concrete, the trade off, of course,is with

workability, since very low water content result in very stiff mixtures that are difficult to

place. The water-to-cement ratio is a factor selected by the civil engineer.

Workability

Workability is one of the physical parameters of concrete which affects the strength and

durability as well as the cost of labor and appearance of the finished product. Concrete is said

to be workable when it is easily placed and compacted homogeneously i.e without bleeding

or Segregation. Unworkable concrete needs more work or effort to be compacted in place,

also honeycombs &/or pockets may also be visible in finished concrete.Definition of

Workability “The property of fresh concrete which is indicated by the amount of useful

internal work required to fully compact the concrete without bleeding or segregation in the

finished product.”

Factors affecting workability:

• Water content in the concrete mix

• Amount of cement & its Properties

• Aggregate Grading (Size Distribution)

• Nature of Aggregate Particles (Shape, Surface Texture, Porosity etc.)

• Temperature of the concrete mix

• Humidity of the environment

• Mode of compaction

• Method of placement of concrete

• Method of transmission of concrete

How to improve the workability of concrete

• Increase water/cement ratio

• Increase size of aggregate

• Use well-rounded and smooth aggregate instead of irregular shape

• Increase the mixing time

• Increase the mixing temperature

• Use non-porous and saturated aggregate

• With addition of air-entraining mixtures

Workability tests:

There are 4 types of tests for workability.They are slump test, compacting factor test, flow

test, and vee bee test

Slump test

The slump test result is a slump of the behavior of a compacted inverted cone of concrete

under the action of gravity. It measures the consistency or the wetness of concrete.Metal

mould, in the shape of the frustum of a cone, open at both ends, and provided with the handle,

top internal diameter 4 in (102 mm), and bottom internal diameter 8 in (203 mm) with a

height of 1 ft (305 mm). A 2 ft (610 mm) long bullet nosed metal rod, (16 mm) in

diameter.Apparatus Required: Compacting Factor apparatus, Trowels, Graduated cylinder,

Balance and Tamping rod and iron bucket

The test is carried out using a mould known as a slump cone or Abrams cone. The

cone is placed on a hard non-absorbent surface. This cone is filled with fresh concrete in

three stages, each time it is tamped using a rod of standard dimensions. At the end of the third

stage, concrete is struck off flush to the top of the mould. The mouldis carefully lifted

vertically upwards, so as not to disturb the concrete cone. Concrete subsides. This subsidence

is termed as slump, and is measured in to the nearest 5 mm if the slump is <100 mm and

measured to the nearest 10 mm if the slump is >100 mm.

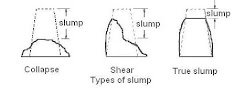

The slumped concrete takes various shapes, and according to the profile of slumped

concrete, the slump is termed as true slump, shear slump or collapse slump. If a shear or

collapse slump is achieved, a fresh sample should be taken and the test repeated. A collapse

slump is an indication of too wet a mix. Only a true slump is of any use in the test. A collapse

slump will generally mean that the mix is too wet or that it is a high workability mix, for

which slump test is not appropriate. Very dry mixes; having slump 0 – 25 mm are used in

road making, low workability mixes; having slump 10 – 40 mm are used for foundations with

light reinforcement, medium workability mixes; 50 - 90 for normal reinforced concrete

placed with vibration, high workability concrete; > 100 mm.

This test is usually used in laboratory and determines the workability of fresh concrete when

size is about 40 mm maximum. The test is carried out as per specification of IS: 1199-1959.

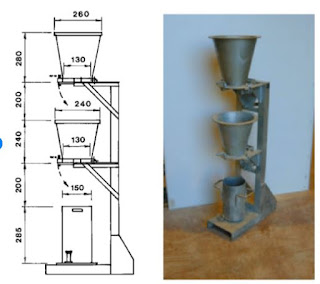

Compacting factor test:

Steps for performing the experiment:

• keep the apparatus on the ground and apply grease on the inner surface of the

cylinders.

• Measure the mass as w1 kg by weighing the cylinder accurately and fix the cylinder

on the base in such a way that the central points of hoppers and cylinder lie on one

vertical line and cover the cylinder with a plate.

• For each 5 kg of aggregate mixes are to be prepared with water-cement ratio by

weight with 2.5 kg sand and 1.25 kg of cement and then add required amount of water

thoroughly until and unless concrete appears to be homogeneous.

• With the help of hand scoop without compacting fill the freshly mixed concrete in

upper hopper part gently and carefully and within two minutes release the trap door so

that the concrete may fall into the lower hopper such that it bring the concrete into

standard compaction.

• Fall the concrete to into the cylinder by bringing the concrete into standard

Compaction immediately after the concrete has come to rest and open the trap door of

lower hopper and then remove the excess concrete above the top of the cylinder by a

pair of trowels, one in each hand will blades horizontal slide them from the opposite

edges of the mould inward to the center with a sawing motion.

• Clean the cylinder from all sides properly. Find the mass of partially compacted

concrete thus filled in the cylinder and say it W2 kg. After this refill the cylinder with

the same sample of concrete in approximately 50 mm layers, by vibrating each layer

heavily so as to expel all the air and obtain full compaction of the Concrete.

• Struck off level the concrete and weigh and cylinder filled with fully compacted

concrete. Let the mass be W3 kg.

• Calculate compaction factor by using the formula: C.F = W2 – W1 / W3 – W1

Flow Table Test:

The flow table test or flow test is a method to determine the consistence of fresh concrete.

Flow table with a grip and a hinge, 70 centimetres (28 in) square.Abrams cone, open at the

top and at the bottom - 30 centimetres (12 in) high, 17 centimetres (6.7 in) top diameter, 25

centimetres (9.8 in) base diameter.Water bucket and broom for wetting the flow

table.Tamping rod, 60 centimetres (24 in) longConducting the testTheflowtable is wetted.The

cone is placed in the center of the flowtable and filled with fresh concrete in two equal layers

layers. Each layer is tamped 10 times with tamping rod.Wait 30 seconds before lifting the

coneThe cone is lifted, allowing the concrete to flow.The flowtable is then lifted up 40mm

and then dropped 15 times, causing the concrete to flowAfter this the diameter of the concrete

is measured.

Vee-Bee Test:

This test is useful for concrete having low and very low workability. In this test the concrete

is moulded into a cone in a cylinder container and the entire set up is mounted on a vibrating

table. When vibrator starts, concrete placed on the cone starts to occupy the cylindrical

container by the way of getting remoulded. Remoulding is complete when the concrete

surface becomes horizontal. The time required for completion of remoulding since start of

vibrator is measured and denoted as vee-bee seconds. This provides a measure for

workability. Lesser is the vee-bee seconds more is the workability

What is Cement? What are the types of cement and their uses?

Composition of Cement clinker and Hydration of Cement

Types of Tests on Cement to Check the Quality

PPC or OPC And Their Difference

All Types of Cement in Construction

Must-Know Points to Check on a Cement Bag Before Buying It

Production of concrete, Batching, Mixing, Compaction and Curing

What is a Cavity Wall? Construction and Advantages of Cavity walls and their perpose

No comments:

Post a Comment

If you are getting more information from civilengineerfriend page please give your comments. Share the page information in your whatsapp group. Subscribe our page to get more information.