1. What are the functions of different components of a typical expansion joint?

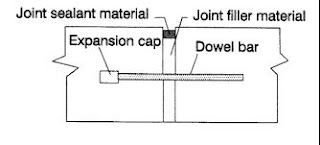

In a typical expansion joint, it normally contains the following components: joint sealant, joint filler, dowel bar, PVC dowel sleeve, bond breaker tape and cradle bent. Joint sealant: it seals the joint width and prevents water and dirt from entering the joint and causing dowel bar corrosion and unexpected joint stress resulting from restrained movement.

Joint filler: it is compressible so that the joint can expand freely without constraint. Someone may doubt that even without its presence, the joint can still expand freely. In fact, its presence is necessary because it serves the purpose of space occupation such that even if dirt and rubbish are intruded in the joint, there is no space left for their accommodation.

|

| What are the functions of different components of a typical expansion joint |

Dowel bar: This is a major component of the joint. It serves to guide the direction of movement of concrete expansion. Therefore, incorrect direction of placement of dowel bar will induce stresses in the joint during thermal expansion. On the other hand, it links the two adjacent structures by transferring loads across the joints.

PVC dowel sleeve: It serves to facilitate the movement of dowel bar. On one side of the joint, the dowel bar is encased in concrete. On the other side, however, the PVC dowel sleeve is bonded directly to concrete so that movement of dowel bar can take place. One may notice that the detailing of normal expansion joints in Highways Standard Drawing is in such a way that part of PVC dowel sleeve is also extended to the other part of the joint where the dowel bar has directly adhered to concrete. In this case, it appears that this arrangement prevents the movement of joint. If this is the case, why should designers purposely put up such arrangement? In fact, the rationale behind this is to avoid water from getting into contact with dowel bar in case the joint sealant fails. As PVC is a flexible material, it only minutely hinders the movement of joint only under this design.

Bond breaker tape: As the majority of joint sealant is applied in liquid form during construction, the bond breaker tape helps to prevent flowing of sealant liquid inside the joint .

Cradle bar: It helps to uphold the dowel bar in position during construction.

2. If on-site slump test fails, should engineers allow the contractor to continue the concreting works?

This is a very classical question raised by many graduate engineers. In fact, there are two schools of thought regarding this issue. The first school of thought is rather straightforward: the contractor fails to comply with contractual requirements and therefore as per G. C. C. Clause 54 (2)(c) the engineer could order suspension of the Works. Under the conditions of G. C. C. Clause 54(2)(a) – (d), the contractor is not entitled to any claims of cost which is the main concern for most engineers. This is the contractual power given to the Engineer in case of any failure in tests required by the contract, even though some engineers argue that slump tests are not as important as other tests like compression test.

|

| If on-site slump test fails, should engineers allow the contractor to continue the concreting works |

The second school of thought is to let the contractor to continue their concreting works and later on request the contractor to prove that the finished works comply with other contractual requirements e.g. compression test. This is based upon the belief that workability is mainly required to achieve design concrete compression strength. In case the compression test also fails, the contractor should demolish and reconstruct the works accordingly. In fact, this is a rather passive way of treating construction works and is not recommended because of the following reasons:

(i) Workability of freshly placed concrete is related not only to strength but also to durability of concrete. Even if the future compression test passes, failing in slump test indicates that it may have adverse impact to durability of completed concrete structures.

(ii) In case the compression test fails, the contractor has to deploy extra time and resources to remove the work and reconstruct them once again and this slows down the progress of works significantly. Hence, in view of such likely probability of occurrence, why shouldn’t the Engineer exercise his power to stop the contractor and save these extra time and cost?

3. What is the function of shear keys in the design of retaining walls?

In determining the external stability of retaining walls, failure modes like bearing failure, sliding and overturning are normally considered in the design. In considering the criterion of sliding, the sliding resistance of retaining walls is derived from the base friction between the wall base and the foundation soils. To increase the sliding resistance of retaining walls, other than providing a large self-weight or a large retained soil mass, shear keys are to beinstalled at the wall base. The principle of shear keys is as follows:

The main purpose of installation of shear keys is to increase the extra passive resistance developed by the height of shear keys. However, active pressure developed by shear keys also increases simultaneously. The success of shear keys lies in the fact that the increase of passive pressure exceeds the increase in active pressure, resulting in a net improvement of sliding resistance.

|

| What is the function of shear keys in the design of retaining walls |

On the other hand, friction between the wall base and the foundation soils is normally about a fraction of the angle of internal resistance (i.e. about 0.8φ ) where φ is the angle of internal friction of foundation soil. When a shear key is installed at the base of the retaining wall, the failure surface is changed from the wall base/soil horizontal plane to a plane within foundation soil. Therefore, the friction angle mobilized in this case is φ instead of 0.8φ in the previous case and the sliding resistance can be enhanced

4. In designing concrete structures, normally maximum aggregate sizes are adopted with ranges from 10mm to 20mm. Does an increase of maximum aggregate size benefit the structures?

To answer this question, let’s consider an example of a cube. The surface area to volume ratio of a cube is 6/b where b is the length of the cube. This implies that the surface area to volume ratio decreases with an increase in volume. Therefore, when the size of maximum aggregate is increased, the surface area to be wetted by water per unit volume is reduced. Consequently, the water requirement of the concrete mixes is reduced accordingly so that the water/cement ratio can be lowered, resulting in a rise in concrete strength.

However, an increase of aggregate size is also accompanied by the effect of reduced contact areas and discontinuities created by these larger sized particles. In general, for maximum aggregate sizes below 40mm, the effect of lower water requirement can offset the disadvantages brought about by discontinuities as suggested by Longman Scientific and Technical (1987).

5. In concrete compression test, normally 150mmx150mmx150mm concrete cube samples is used for testing. Why isn’t 100mmx100mmx100mm concrete cube samples used in the test instead of 150mmx150mmx150mm concrete cube samples?

Basically, the force supplied by a concrete compression machine is a definite value. For normal concrete strength application, say below 50MPa, the stress produced by a 150mmx150mmx150mm cube is sufficient for the machine to crush the concrete sample. However, if the designed concrete strength is 100MPa, under the same force (about 2,000kN) supplied by the machine, the stress under a 150mmx150mmx150mm cube is not sufficient to crush the concrete cube. Therefore, 100mmx100mmx100mm concrete cubes are used instead to increase the applied stress to crush the concrete cubes.

For normal concrete strength, the cube size of 150mmx150mmx150mm is already sufficient for the crushing strength of the machine.

6. What are the major problems in using pumping for concreting works?

In pumping operation, the force exerted by pumps must overcome the friction between concrete and the pumping pipes, the weight of concrete and the pressure head when placing concrete above the pumps. In fact, as only water is pumpable, it is the water in the concrete that transfers the pressure.

The main problems associated with pumping are the effect of segregation and bleeding. To rectify these adverse effects, the proportion of cement is increased to enhance the cohesion in order to reduce segregation and bleeding. On the other hand, a proper selection of aggregate grading helps to improve the pumpability of concrete.

|

| What are the major problems in using pumping for concreting works |

7. Is it desirable to use concrete of very high strength i.e. exceeding 60MPa? What are the potential problems associated with such high strength concrete?

Increasing the strength of concrete, say from 40MPa to 80MPa, it definitely helps in improving the structural performance of the structure by producing a denser, more durable and higher load capacity concrete. The size of concrete members can be significantly reduced resulting in substantial cost savings. However, an increase of concrete strength is also accompanied by the occurrence of thermal cracking. With an increase in concrete strength, the cement content is increased and this leads to higher thermal strains. Consequently, additional reinforcement has to be introduced to control these additional cracks caused by the increase in concrete strength. Moreover, the ductility of concrete decreases with an increase in concrete strength. Attention should be paid during the design of high strength concrete to increase the ductility of concrete. In addition, fire resistance of high strength concrete is found to be less than normal strength concrete as suggested by Odd E. Gjorv (1994).

Though the tensile strength of high strength concrete is higher than that of normal concrete, the rate of increase of tensile strength is not proportional to the increase of compressive strength. For normal concrete, tensile strength is about one-tenth of compressive strength.

However, for high strength concrete, it may only drop to 5% of compressive strength. Moreover, owing to a low aggregate content of high strength concrete, creep and shrinkage increases.

8. What are the disadvantages of curing by ponding and polythene sheets?

The purpose of curing is to reduce the rate of heat loss of freshly placed concrete to the atmosphere and to minimize the temperature gradient across concrete cross section. Moreover, curing serves to reduce of the loss water from freshly placed concrete to the atmosphere.

Ponding: This method of thermal curing is readily affected by weather condition (cold wind). Moreover, a large amount of water used has to be disposed off the construction sites after curing.

Polythene sheet: This method of curing is based on the principle that there is no flow of air over the concrete surface and thereby no evaporation can take place on top of the freshly concreted surface by provision of polythene sheets. However, it suffers from the demerit that polythene sheets can be easily blown off in windy condition and the performance of curing would be affected. Moreover, for water lost due to self-desiccation, this method cannot replenish these losses.

9. Comparing the rate of “Formwork exceeding 300mm wide, horizontal or at any inclination up to and including 5o to the horizontal” with the rate of “Formwork exceeding 300mm wide, at any inclination more than 85o up to and including 90o to the horizontal”, which one is higher?

The item “Formwork exceeding 300mm wide, at any inclination more than 85o up to and including 90o to the horizontal” refers to formwork formed vertically and when compared with formwork erected in horizontal plane, the amount of falsework required is smaller.

The item “Formwork exceeding 300mm wide, horizontal or at any inclination up to and including 5o to the horizontal” refers to formwork to be erected in horizontal position and in general it requires much falsework to support this type of formwork. Therefore, the rate for this item is higher than the one mentioned in the above paragraph

10. If concrete compression test fails, should Schmidt hammer test be adopted as an alternative test to prove the concrete strength?

The Scmidt hammer test is based on the elastic rebound of hammer which presses on concrete surface and it measures the surface hardness of concrete. Since the test is very sensitive to the presence of aggregates and voids at the concrete surface, it is necessary to take more than 10 readings over the area of test. However, it should be noted that Schmidt hammer test measures surface hardness only but not the strength of concrete. Therefore, it may not be considered a good substitute for concrete compression test.

11. What is the indication of shear slump and collapse slump in slump tests?

There are three types of slump that may occur in slumps test, namely, true slump, shear slump and collapse slump.

True slump refers to general drop of the concrete mass evenly all around without disintegration.

Shear slump implies that the concrete mix is deficient in cohesion. Consequently, it may undergo segregation and bleeding and thus is undesirable for durability of concrete.

Collapse slump indicates that concrete mix is too wet ad the mix is deemed to be harsh and lean.

12. In erection of falsework, for a rectangular panel inside a falsework should it be braced along the two diagonals?

When a rectangular panel is subject to an eccentric load or a lateral load, it tends to deform into a parallelogram with one diagonal shortening and the other elongating. Theoretically, it is sufficient to brace along one of the diagonals (the one in tension). If one diagonal is only allowed to brace inside the rectangular panel, it should be not braced in the diagonal in compression because under severe lateral loading the diagonal may buckle leading to failure of structure.

However, in actual situation lateral loads may come from both sides of the panel and hence it should be braced in both diagonals.

13. In carrying out compression test for concrete, should test cubes or test cylinders be adopted?

Basically, the results of compression test carried out by using cubes are higher than that by cylinders. In compression test, the failure mode is in the form of tensile splitting induced by uniaxial compression. However, since the concrete samples tend to expand laterally under compression, the friction developed at the concrete-machine interface generates forces which apparently increase the compressive strength of concrete. However, when the ratio of height to width of sample increases, the effect of shear on compressive strength becomes smaller. This explains why the results of compression test by cylinders are lower than that of cubes. Reference is made to Longman Scientific and Technical (1987).

14. What is the function of rebate in a typical construction joint?

Construction joints are created on sites to facilitate the construction process. However, if improperly constructed, the completed construction joints will leave an uneven scar on the concrete surface and affect significantly its appearance. To avoid this, a rebate is formed during the first pour of one side of construction joint. After the other pour is concreted, it will hide the uneven joint inside the rebate.

|

| a rebate |

No comments:

Post a Comment

If you are getting more information from civilengineerfriend page please give your comments. Share the page information in your whatsapp group. Subscribe our page to get more information.