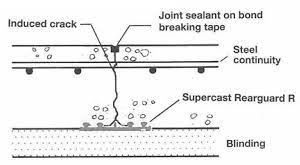

1. What is the function of waterstops in joints of box culverts and drainage channels?

The principal function of waterstops is to prevent liquids (e.g. water), water-borne materials and solids to pass through concrete joints. In essence, it aims at providing watertightness to the drainage channel. Besides, waterstops in drainage channels or box culverts can also serve two other purposes:

|

| What is the function of waterstops in joints of box culverts and drainage channels |

(i) to avoid water contacting joints’ dowel bars and causing corrosion.

(ii) to avoid water seeping in from the underside of drainage channels or box culverts, thereby washing in soil particles and causing voids underneath these structures and finally leading to their failure. To serve the second purpose, obviously only one waterstop is required at any depth location. To serve the first purpose, a waterstop has to be installed on top of dowel bars to prevent water from drainage channels from leaking through. On the other hand, a waterstop has to be provided below dowel bars to avoid underground water from surging upwards. In fact, the other way out to serve the first purpose is by using corrosion-resistant bars.

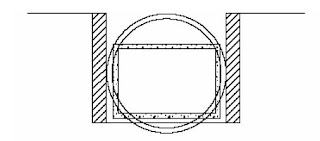

2. What are the differences in applications between pipe culverts and box culverts?

Basically, a culvert means a covered hydraulic structure which conveys fluid. Therefore in a broad sense, pipe culverts in a small scale represent normal pipes like precast concrete pipes. In terms of hydraulic performance, circular section is the best geometrical sections among all.

Therefore, for relative small discharge, precast concrete pipes and ductile iron pipes are normally used which are circular in shape. But for applications of very large flow, precast concrete pipes and ductile iron pipes may not be available in current market. In this connection, cast-in-situ construction has to be employed. It is beyond doubt that the fabrication of formwork for circular shape is difficult when compared with normal box culvert structures. However, circular shape is the most hydraulic efficient structure which means for a given discharge, the area of flow is minimum. Therefore, it helps to save the cost of extra linings required for the choice of box culverts. However, box culverts do possess some advantages. For example, they can cope with large flow situation where headroom is limited because the height of box culverts can be reduced while the size of pipe culverts is fixed. Secondly, for some difficult site conditions, e.g. excavation of structure in rock, for the same equivalent cross-sectional area, the width of box culverts can be designed to be smaller than that of pipe culverts and this enhances smaller amount of excavation and backfilling.

|

| Small spatial requirement of box culver |

3. What are the limitations of Rational Method in calculating runoff?

Computation of runoff is a complicated matter which depends on many factors like the ground permeability, rainfall duration, rainfall pattern, catchment area characteristics etc. Basically, Rational Method is a means to find out the maximum discharge suitable for design purpose. In this method, it is assumed that the rainfall duration is the same as the time of concentration and the return period of rainfall intensity is the same as the peak runoff. Time of concentration refers to the time required for the most remote location of stormwater inside the catchment to flow to the outlet. When the time of concentration is equal to the rainfall period, the maximum discharge occurs and rainfall collected inside the catchment comes to the same outlet point. Rational Method provides the peak discharge only and it cannot produce a hydrograph. If a more detailed pattern of runoff is required, unit hydrograph or other methods have to be used. The accuracy of rational method depends very much on our correct selection of runoff coefficient and delineation of catchment area. Rational Method is a rather conservative method. One of the basic assumptions of the rational formula is that the rainfall intensity must be constant for an interval at least equal to the time of concentration. For long duration of rainfall, this assumption may not hold true. Moreover, the runoff coefficient in Rational Method is difficult to be determined accurately and it depends on many factors like moisture condition of soils, rainfall intensity and duration, degree of soil compaction, vegetation etc. In addition, In Rational Method the runoff coefficient is independent of rainfall intensity and this does not reflect the actual situation.

4.Why are some manhole covers made of cast iron while some are made of ductile iron?

Traditionally, manholes covers are made of cast iron. However, in the viewpoint of pipe maintenance, frequent opening of manhole covers has to be carried out. Therefore, it poses potential safety hazard to the workers during the lifting-up process of manhole covers because cast iron manhole covers are very heavy to normal workers. Consequently, research has been conducted and ductile iron is considered as a better choice than cast iron because it can resist the same traffic loads with lower self-weight. Moreover, as ductile iron is less brittle than cast iron, the traditional cast iron manhole covers are more susceptible to damage and thus requires higher maintenance cost.However, ductile iron manhole covers do suffer from some demerits. For instance, owing to their relative low self-weight, vehicles passing over these manhole covers would lead to the movement of covers and generate unpleasant noises. To solve this problem, instead of increasing the self-weight of ductile iron manhole covers which similarly causes safety problems to workers during regular maintenance, the covers can be designed to be attached to the manhole frames which hold them in firm position.

5. Why is it preferable to design stormwater drains to match soffit?

Stormwater drains collect stormwater in their corresponding catchment areas during rainstorm and convey the collected water through outlets to the sea. Therefore, in considering the hydraulic design of stormwater drains, other than normal drainage pipe capacity to be taken into consideration, one should check the backwater effect due to tidal condition at outlets if the drains are located quite close to the downstream end of outlets. Stormwater drains are normally designed to match soffit to avoid surcharging by backwater effect or when the downstream pipes are running full. Normally pipe size increases from upstream to downstream. For the case of matching drain invert, when outlet pipes are fully surcharged by tidal effect of the sea or when the downstream pipes are fully filled with stormwater, pipe sections immediately upstream of the outlet are also surcharged too. However, for the case of matching pipe soffit, the immediate upstream sections of outlet pipes are not totally surcharged even though downstream pipes are running full. However, it is not always practical to maintain soffit for all pipelines because it requires sufficient drop to achieve this. Moreover, the flow of stormwater is mainly by gravity in the design of stormwater drains. In case the drains are designed to match invert, then it stands a high probability that the flow in the upstream smaller pipes has to be discharged against a head.

Note: Matching soffit means that all pipelines are aligned continuously with respect to the pipelines’ crown level.

|

| Match soffit VS match invert. |

Inverted siphons are designed at locations in which a sewer system is blocked by underground utilities or stormwater drains. They are sometimes called depressed sewers because it is claimed that there is no actual siphon action. They connect the upstream and downstream sewers with U-shaped vertical alignment such that they are always running full. The drawbacks of inverted siphons are:

(i) They induce additional head loss to the sewer system which is undesirable in hydraulic performance;

(ii) U-shaped siphons create sediment accumulation problem and previous experience showed that inverted siphons were easily blocked due to siltation;

(iii) Maintenance of invert siphons is difficult due to its inaccessibility.

7. What is the mechanism of cavitation in pipes and drains?

Cavitation refers to the formation of air bubbles in fluid in low-pressure condition which is lower than the saturation pressure. It is a potentially damaging condition in which the fluid in pipes or sewers is at high velocities. By Bernoulli’s Equation, at high flow velocities, the pressure head of fluid is reduced accordingly. As the fluid pressure is less than saturation pressure, dissolved gases are released from the fluid and these air bubbles will suddenly collapse when the flow enters into a region of higher pressure. This produces a high dynamic pressure which causes damage to the pipelines due to its high frequency.

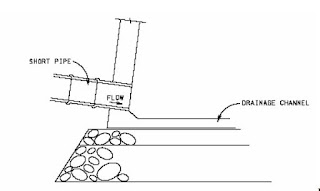

8. When a drainage system (i.e. u-channels with catchpits) is connected to a main drainage channel, a segment of short pipe is used. What is the reason of such arrangement?

There are three scenarios of such connection arrangement: (a) a new drainage system is connected to an existing drainage channel (b) an existing drainage system is connected to a new drainage channel (c) a new drainage system is connected to a new drainage channel. For all scenarios, what engineers consider is the total amount of differential settlement or lateral movement to be encountered between the drainage system and main drainage channel. For scenario (b) and (c), it is very likely that substantial differential settlement will occur and this will cause damage to the connecting concrete pipes. Therefore a segment of short pipes are designed so that they serve to provide flexibility to the pipes in case of uneven settlement occurring between drainage system and main drainage channels.

|

| Short pipe. |

9. What are the functions of bedding under stormwater drains?

Bedding, which are normally made of granular materials or concrete, serves four main functions as suggested by O. C. Young and J. J. Trott:

(i) To enhance a uniform support under pipes in order to reduce the bending moment longitudinally;

(ii) To increase the load-supporting strength of the pipes;

(iii) For pipes with spigot and socket joints, it enables pipes to be supported along pipe lengths instead of pipe sockets. Otherwise, uneven stress may be induced and it may damage the pipes;

(iv) To provide a platform for achieving correct alignment and level during and after construction.

10. In designing sewer pipes, why are vitrified clay pipes commonly used for pipe size less than 600mm while precast concrete pipes with PVC lining is used for pipe size exceeding 600mm?

The market price of vitrified clay pipes is generally less than that of precast concrete pipes with PVC lining. Therefore, for small size of pipes (pipe diameter less than 600mm) it is more economical to use vitrified clay pipes. However, vitrified clay pipes do suffer from the problem of brittleness and its effect is even severe for larger size of pipes. Moreover, it is rather time consuming to deliver clay pipes products because the majority of them are manufactured in Europe. Hence, for larger size of sewer pipes (diameter more than 600mm) it is customary to use precast concrete pipes with PVC lining.

11. Nowadays, most flap valves are made of HDPE. What are the advantages of using HDPE when compared with cast iron?

(i) It has no reaction with sewage and seawater and does not suffer from the corrosion problem associated with cast iron.

(ii) No protective coating is required and it is almost maintenance-free.

(iii) HDPE flap valves require very low opening pressure in operation (like 5mm water level difference). For cast iron flap valves, due to its own heavy self-weight, the required opening pressure of cast iron flap valves is higher than that of HDPE flap valves. This criterion is essential for dry weather flow conditions. However, the pressure resistance of HDPE flap valves is not as good as cast iron flap valves. For instance, a typical 450mm wide HDPE flap valve can only withstand about 5m water column.

12. What are the functions of the following features observed in a typical manhole?

(i)groove near benching, (ii) R.S.J. (iii) double seal manhole cover and (iv) u-trap with rodding arm.

(i) The groove is used to facilitate the maintenance of manholes and sewer/drain pipes. Shutoff boards are erected on the grooves during maintenance operation so that water flow coming from upstream is terminated in the manhole and backwater from downstream is also blocked. In addition, the groove also facilitates water flow diversion for routine maintenance operation.

(ii) R.S.J. is a small-scale size of universal beams and is used for resisting the high stresses incurred by heavy traffic loads acting directly on the upper narrow projected section of manholes.

(iii) Double seal terminal manhole covers are used for sealing off gases emitted inside sewer/drains and prevent them from releasing out of the manhole.

(iv) U-trap with rodding arms is also used for sealing off unpleasant gas smell by the trapped u-shaped water columns. Rodding arm is normally closed with rubber rings during normal operation. However, during maintenance operation, the rubber ring is removed and rodding can be carried out through the rodding arm.

13. The spacing of manholes in straight sections for different pipe sizes is stated in Stormwater Drainage Manual. How are these figures arrived at?

For pipe size < 300mm, rodding is usually adopted in which workers place about 1m long rods through the pipes to the location of blockage and manually operate the rod to clear the blockage. For pipe size < 700mm, water-jetting is normally employed in which water is supplied from nearby fire hydrants and pressurized water jet is used for clearing blockage. Winching method is adopted for all sizes of pipes. For instance, for pipe size exceeding 1050mm, it is stated in Stormwater Drainage Manual that maximum intervals between manholes along straight lengths should be 120m. This is because for sizes over 1050m, the main method of pipe maintenance is by winching whose maximum length of operation is 120m. Similarly, the maximum intervals of manholes for other straight pipes are derived from their corresponding maintenance methods.

14. In selection of dams in drainage channels, what are the advantages of using rubber dams instead of steel-gate dams?

The advantages of rubber dams are as follows:

(i) Since rubber is flexible in nature it is capable of performing deflation even in the presence of dirt and sedimentation on the downstream side. However, for rigid steel-gate dams, it may not be possible to open when there is excessive sediment.

(ii) Since the foundation of rubber dams is comparatively lighter than that of steel-gate dams, it saves both construction cost and time.

(iii) Rubber dams can be designed with longer spans without piers while steel-gate dams require intermediate piers for long spans.

15. Should air test or water tests be selected to test the leakage of constructed gravity pipelines?

For gravity pipes, air tests or water tests are carried out after completion of laying and jointing of the pipes. These tests are conducted to check the watertightness of joints and to ensure the pipelines are free from damage where leakage may occur. Air test has the advantage that the test itself is simple and faster to be carried out. It does not require the disposal of significant quantities of water used in the test which is a mandatory requirement for water test. However, in case leakage exists in the constructed segment of gravity pipelines, the position of leakage can hardly be located in air test. Moreover, the rate of water leakage cannot be determined from air tests. In addition, air test is readily affected by atmospheric condition because air has a relatively high coefficient of thermal expansion. The test is also influenced by the moisture condition of the test pipelines because it affects the passage of air through the pipelines. For water test, though it is comparatively slow, it can detect the location of water leakage. However, the leakage rate results from water test may not truly reflect its actual leakage because pipeline materials like concrete and clay are porous and would absorb water during the test.

16. In designing of access ramps for drainage channels, why should the direction of access ramps be sloping down towards downstream?

In the design of access ramps, the direction is normally specified to be sloping down towards downstream so as to avoid the occurrence of over-shooting of flowing water for supercritical flow in case of aligning the ramps in the reverse direction of channel flow.

Note: Access ramps refer to ramps used for maintenance vehicles during routine maintenance of channels.

17. When branch pipelines are connected to main pipelines, sometimes Y-junctions or fitting branched pipelines to main pipelines by formation of holes in main pipelines are used. Which one is a better choice?

By using standard precast units of Y-junction branch pipelines, it is beyond doubt that joints between branched pipelines and main pipelines are properly formed and the quality of joints is relatively less dependent on workmanship. However, it suffers from the problem that with fixed precast units of Y-junctions, sometimes it may be difficult for contractors to determine the precise orientation of specific angles of Y-junctions with respect to gullies. (e.g. gullies are connected through side branches to carrier drains) By forming elliptical holes in main pipelines and fitting the side branches into them with cement mortar, the quality of pipe joints is highly dependent on workmanship. It is commonly found that in subsequent CCTV inspections side branches are projected inside main pipes. This is undesirable because the projected side branches reduce the cross sectional area of main pipes locally and affect their hydraulic performance. Moreover, the projected side pipes may trap rubbish and dirt in the vicinity. On the other hand, cement mortar may not be properly applied at connection joints because these areas are hidden from view and are difficult to be inspected by engineers. Therefore, in selecting between the two available methods, engineers should make their own judgments based on the above considerations.

|

| Y-junction in drainage pipes. |

18. Rational Method should not be used for large catchments in estimating peak runoff. Is it true?

Rational Method is suitable for small catchments only because the time of concentration of small catchments is small. In Rational Method the peak runoff is calculated based on the assumption that the time of concentration is equal to the rainfall duration. For small catchments, this assumption may hold true in most circumstances. One of the assumptions of Rational Method is that rainfall intensity over the entire catchment remains constant during the storm duration. However, in case of a large catchment it stands a high probability that rainfall intensity varies in various part of the large catchment. In addition, for long duration of rainfall, it is rare that the rainfall intensity remains constant over the entire rainstorm and a shorter duration but a more intense rainfall could produce a higher peak runoff. Moreover, a reduction of peak runoff is also brought about by the temporary storage of stormwater like channels within the catchment. In actual condition, the runoff rate within the catchment varies from place to place because of different soil properties and past conditions. As suggested by Bureau of Public Roads (1965), sometimes the peak discharge occurs before all of the drainage area is contributing. For instance, when a significant portion of drainage area within the catchment has very small time of concentration so that a higher rainfall intensity can be used for this portion, the runoff coming solely from this portion is higher than that of the whole catchment in which a lower rainfall intensity is adopted because the remaining part of the catchment has comparatively large time of concentration. Therefore, this results in incorrect estimation of peak runoff of large catchments if Rational Method is adopted.

19. What is the purpose of carrying out water absorption test for precast concrete pipes?

Cement will mix with more water than is required to eventually combine during hydration of cement paste. As such, some voids will be left behind after the hydration process which affects the strength and durability of concrete. With the presence of air voids in concrete, it is vulnerable to penetration and attack by aggressive chemicals. Good quality concrete is characterized by having minimal voids left by excess water and therefore, water absorption test for precast concrete pipes is adopted for checking the quality of concrete in terms of density and imperviousness.

No comments:

Post a Comment

If you are getting more information from civilengineerfriend page please give your comments. Share the page information in your whatsapp group. Subscribe our page to get more information.