Benefits of Plywood in construction

Plywood is very widely used in construction. This is because it has many useful properties that are suitable for construction. Plywood is a factory-produced material that has precise dimensions made from three or four sheets of wood. These sheets are glued together to form a thicker sheet. Plywood is very light in weight and very durable. It can be used in both the interior and exterior areas of a building. That is why it is so commonly preferred by builders and house owners.

Properties of Plywood

Very high strength

Plywood has the physical strength of the wood it is made from. The veneer design is

made into also adds to its strength. An entire sheet of plywood is resistant to splitting

especially when nailed at the corners. There is a balanced strength on the whole sheet.

This also increases its stability. Plywood also has a very high strength to weight ratio

when compared to cut lumber.

|

| Very high strength |

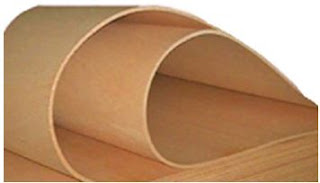

Flexibility

Plywood is very convenient to cut and can be used to fit every requirement in

construction, unlike timber. The main advantage is that the thickness of each sheet can

be changed according to its purpose. The number of sheets used can vary from three

to a few more depending on the pliability required. A thinner sheet will have more

flexibility and hence, can be used for panels and ceilings.

|

| Flexibility |

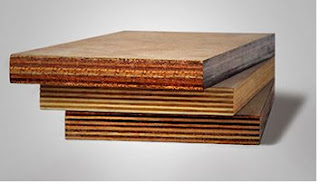

Strong Panel Sheer

Plywood is made by combining an odd number of sheets. This makes it resistant to

bending. Each grain of the plywood is placed at an angle of 90 degrees. These fine-grained veneers are at an angle of 30 to 45 degrees from each other. This increases its

strength in every direction. This cross lamination technology is useful in fabricated

panels or for bracing.

|

| Strong Panel Sheer |

Impact-resistant

Due to cross lamination, plywood has very high tensile strength. This makes it able to

withstand an overload of up to twice its predesigned tolerance. This is because cross

lamination allows the entire force to be distributed over a large area instead of

concentrating on a particular spot. This is very crucial, especially when withstanding

high winds or sudden seismic activities.

|

| Impact-resistant |

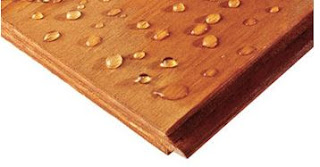

Moisture resistant

Plywood is resistant to moisture and humidity. That is why it is highly preferred while

constructing the exteriors of a building. Adding a layer of varnish or water repellent

adhesive will increase its resistance to moisture and water damage. Moisture resistance

has many applications in the marine industry. They can be used for sheds, cladding,

etc. They are also used for holding concrete while setting. In the interior, they are used

on the floors of houses. Plywood does not shrink or rot when exposed to water or

very high temperatures.

|

| Moisture resistant |

Chemical resistant

Plywood is resistant to corrosion due to chemicals. This makes it suitable for use in

constructing coolant towers and chemical works in factories.

|

| Chemical resistant |

Fire resistant

Plywood is generally combined with non-combustible materials like fiber cement. It

can also be coated with a chemical coating that is fire-resistant. This makes it ideal for

building fire-resistant buildings

|

| Fire resistant |

Good Insulator

Plywood is known to have high thermal and sound insulation. This makes it ideal for

use in the music industry in recording studios, etc. It can also be used in walls, floors, and the ceilings of houses to make it soundproof.

Applications of Plywood in Construction

·

Plywood is used as molding support for wet concrete.

·

To make furniture such as cabinets, cupboards, tables, etc.

·

To make lightweight doors and windows.

·

Plywood is also used while making floors.

·

Can be used for building external walls and wall partitions.

·

Also used for packaging applications

No comments:

Post a Comment

If you are getting more information from civilengineerfriend page please give your comments. Share the page information in your whatsapp group. Subscribe our page to get more information.