FLOOR FINISHES AND HOW TO CHOOSE THEM

When choosing a floor finish, keep in mind the following:

How slippery or smooth it is; do not use very smooth finishes in bathrooms and balconies

How abrasion-resistant it is - do not use soft, quick-wearing finishes in areas with heavy foot traffic. Marble and wood have low abrasion resistance, for example, and granite and cement tiles have high abrasion resistance.

Whether it is chemically neutral - some finishes react with acids, and should not be used in kitchens

The climate: wood and carpets are perceived to be warm, so use them in cold climates, and stone and tile are perceived to be cool, so use them in warm climates - unless you have underfloor heating or cooling, which changes things.

A detailed description of each of the most important floor finishes follows.

STONE

Stone is a great floor finish and is affordable in many countries; Italy and India are both known for the variety and quality of stone they produce. There is a great advantage to stone that is almost unique to floor finishes: you can polish it, and thus make it look and feel like new, at any time in its life.

Granite is a volcanic rock (it was originally lava, that cooled to form solid rock) that has the following properties:

It is very hard, strong, and abrasion resistant

It is resistant to acids

It can be polished to a mirror-like smoothness

These properties make it a great choice as a floor or countertop finish. It can also be used to clad walls. However it is available mainly in dark colours - black, red, grey - with the possible exception of Kashmir White Granite. This darkness in colour does tend to limit its use in certain areas.

|

| Granite |

Its surface can also be worked to produce a variety of textures other than smooth: granite can be flamed, water blasted, sand blasted, bush hammered, or tumbled. These rough finishes are mostly used outdoors, on pathways. The famous cobblestones of Europe are granite, for instance.

Marble is a metamorphic rock (meaning that it was made by the intense pressures and heat deep within the earth), and has the following properties:

Most marbles are soft, and not very abrasion resistant

They are not resistant to acids

They can be polished to a mirror finish

It is translucent - light can pass through it to the extent of a few millimeters

Thus, marbles should not be used in high-traffic areas such as the entryways or staircases of public buildings - granite would be much better in those cases. Since it is not acid resistant, you should not use Marble under urinals (urine is acidic), and in kitchens, where lemon juice and other acids are present. But marble is prized for the beauty and richness of its finish; it also feels very special underfoot. It is available in a wide variety of colours, mainly light colours.

|

| Marble |

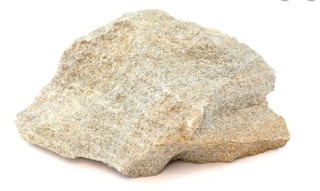

Sandstone is a sedimentary rock (rock formed by ancient rivers that slowly deposited material on their beds, that built up layer by layer over millions of years). It has the following properties:

It is abrasion resistant, but not always strong, as it is formed in layers.

It is usually highly resistant to acids

It has a rough finish, and cannot be mirror-polished, as it consists of grains

These properties mean that it is good for decks and external areas because of its anti-slip properties. Since sandstone looks and feels very different from granite and marble, it has become fashionable to use these in boutique stores. Steve Jobs famously saw a bluish-grey sandstone on a trip to Florence, and many years later insisted that that very stone be used in all apple stores because of its 'integrity. The stone is quarried from an area reserved for apple, cut into tiles, and every piece graded individually for colour tone by master craftsmen. The tiles are then arranged so that pieces with similar colour are placed together, which makes them seem more uniform to the eye. It is obtained from this quarry if you're interested.

|

| Sandstone |

READ MORE

No comments:

Post a Comment

If you are getting more information from civilengineerfriend page please give your comments. Share the page information in your whatsapp group. Subscribe our page to get more information.