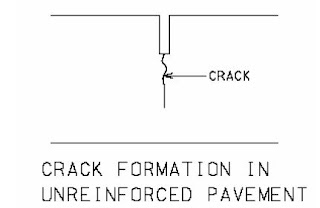

1. How can unreinforced concrete pavement function without mesh reinforcement?

For concrete carriageway, it is normally classified into two types: reinforced and unreinforced concrete pavement. The reinforcement in reinforced carriageway (in the form of mesh) is used for controlling cracking. Then one may query how unreinforced pavement can control cracking without the use of mesh reinforcement. To answer this question, one should pay attention to the features of unreinforced concrete pavement. In accordance with Highways Standard Drawing No. H1109, an approximately 3mm wide groove with a depth of about one-third to one-fourth of slab thickness is designed with a regular spacing (normally 5m). The grooves are designed to be too narrow for stones to fall into when the cracks are open due to concrete contraction. The sectional area in which the groove is located is a plane of weakness and thus this groove acts a potential crack-inducing device in which any potential cracks due to shrinkage and thermal contraction may form. Consequently, the cracks are formed at the base of the groove and thus it would not cause any unpleasant visual appearance on the exposed surface of unreinforced concrete pavement.

2. Why are concrete profile barriers designed with curved surface profiles?

Safety fencings are designed to contain vehicles in the carriageway in which they are traveling and prevent them from rebounding into the road and causing hazards. For normal fencing design, when vehicles crash into safety fencings, it will give way so as to absorb as much energy as possible, thus reducing the impact forces on the vehicles. Moreover, it serves to realign the vehicles along the carriageway when vehicles hit on them. However, for concrete profile barriers they are not designed to absorb energy during vehicle crashing, but to hold the vehicles hitting on them. In this connection, concrete profile barriers are designed with curved profiles so that vehicles can mount and go up partly on them, and yet they will not cause overturning of vehicles. Reference is made to Arthur Wignall, Peter S. Kendrick and Roy Ancil. For shallow-angle crashing of cars, they would climb on the lower slope face of concrete profile barriers. On the other hand, when a car hits at a large angle to the barrier, thebumper collides with the upper sloping face of concrete profile barrier and the car ridesupwards. This provides the uplift of the car whose wheels move up the lower sloping face of the barrier. It is not intended to lift the car too high, otherwise it may result in rolling. Since the friction between the wheels and barriers provide extra lifting forces, it is undesirable to design rough finish on these faces. In essence, the kinetic energy of the car during collision is transformed to potential energy during its lifting up on profile barrier and finally converted back to kinetic energy when the car returns to the road.

Note: For details of concrete profile barriers, reference is made to HyD Standard Drawing No. H2101A.

3. Should joints of concrete kerbs be in line with the joints in concrete carriageway?

In normal practice, joints are provided in road kerbs to cater for concrete expansion and contraction. However, the location of joints in kerbs is not arbitrary and they should match with joints in concrete carriageway. Otherwise, it is very likely that cracks may form in concrete kerbs at location of pavement joints (Ministry of Transport (1955)).

4. Why is the slump specified in concrete carriageway comparatively low (30mm)when compared with normal concrete (75mm)?

The slump of concrete carriageway is purposely specified to be a relatively low value, i.e. 30mm. For concrete carriageway, traffic loads directly act on concrete pavement surface and therefore the surface strength is detrimental to its future performance. In freshly placed concrete, segregation (may be in the form of bleeding) occurs within the mixture of cement paste and aggregates. The degree of resistance to segregation is related to workability of concrete. If substantial segregation is allowed to take place, then the relatively porous and weak laitance layer will be formed on the carriageway surface and the aggregates will concentrate in the bottom. Hence, concrete which has insignificant bleed possesses a stronger surface layer and is more abrasion resistant. Consequently, a small slump value is specified to increase the wearing resistance of concrete and to achieve a suitable surface texture of concrete pavements. Moreover, a low-slump concrete facilitates the use of slipforms when constructing the concrete pavement. With concrete of a low slump value, it still remains its compacted shape and is not liable to deform when the paving machines go away. However, if a high slump concrete is used instead, the pavement surface would drop and the edges may deform readily.

5. Can all utility detectors detect the depth of utilities?

In Hong Kong, underground utility detectors are normally divided into two types: electromagnetic detector and ground penetrating radar (GPR). For electromagnetic detector, it can detect the signals emitted by metallic utilities themselves by passive mode. While in active mode, the detector has to pick up the signals through a transmitter and sonda connected directly to the non-metallic utility. Both the alignment and depth can be found in active mode while only alignment can be found in passive mode. The electromagnetic detector available in market can detect utilities up to depth of 3m. For ground penetrating radar, it sends radio waves into the ground and receives signals from reflections from utilities. It has the advantage of locating both the depth and alignment of utilities. More importantly, it can detect both metallic and non-metallic utilities. However, it suffers from the disadvantage that it is quite expensive and interpretation of data is not simple. Reference is made to LD, DSD (2000).

6. What is the importance of air void content in bituminous pavements?

The air void content of bituminous materials is an important control parameter for the quality of bitumen being laid and compacted. If the air void content is too high, it allows for intrusion of air and water. Moreover, it also increases the rate of hardening of binders which produce premature embrittlement of pavements. In addition, too high a void content will also lead to differential compaction subject to traffic loads and result in formation of ruts and grooves along the wheel track. However, a minimum amount of air void should be maintained to avoid instability during compaction process and to provide space for bitumen flow in long-term consolidation under traffic loads. A sufficient amount of air voids should be designed to make room for expansion of binder in summer and compaction by road traffic as suggested by National Association of Australian State Road Authorities (1968), otherwise bleeding and loss of stability may occur and the pavement will deform readily under severe loads.

7. In concrete pavement, why is the requirement of 95% by mass of quartz grains are specified in contract?

In General Specification of Civil Engineering Works (1992 Edition), in Clause 10.09 it states “Fine aggregate for concrete shall be natural river-deposited sand consisting of at least 95% by mass of quartz grains”. The aim of such specification is to control the quality of river sand. As quartz is a durable and hard material, using a high percentage of quartz in aggregates of concrete can enhance the strength and durability of the surface texture of concrete carriageway. In addition, such specification requires a high percentage of quartz content, thereby reducing the probability of presence of impurities like shell.

8. What is the load transfer mechanism for paving blocks in pedestrian footway?

In Hong Kong, footway is normally designed with paving slabs/interlocking blocks instead of concrete because the extensive use of concrete in pavement is boring. Moreover, poor appearance will result in concrete pavement due to frequently trench openings for utility work. In addition, owing to the prolonged setting and curing time of concrete, the use of concrete pavement inevitably generates disturbance to the general public. The pedestrian loads are taken up through the following ways:

(i) Load carrying capacity of paving slabs/interlocking blocks are derived from their individual strength;

(ii) Pedestrian loads are also supported by interlocking forces provided by friction transfer through the sand in vertical joints (K. K. Tang & Robert P. Cooper (1986)).

9. What is the function of a sand layer underlying paving slab/interlocking blocks?

Normally after the laying of sub-base layer of the paving slab/interlocking blocks, a 30mm thick sand bedding is screeded and tamped over the pavement area. Then paving slabs are laid horizontally with joints of 2-3mm wide and are laid in uphill direction. After completing the laying of paving slabs, sand used for filling joints is spread over the surface of the units and brushed into the joints such that all joints are completely filled. The paving slabs are then bedded into final position by using plate vibrators. The sand layer serves the same purpose of normal blinding layer under concrete structure:

(i) Provide a level and flat surface for the paving slab/interlocking blocks to lay on;

(ii) Protect the foundation (i.e. underground subgrade and sub-base layer) against adverse outside conditions (e.g. bad weather) during construction of the laying work of paving slab/interlocking blocks.

10. What is the function of longitudinal joints in concrete road pavements?

A longitudinal joint consists of a tie bar placed at the mid-depth of a concrete pavement and it is not intended for joint lateral movement. Then one may doubt the reasons of placing longitudinal joints in concrete pavements. In fact, longitudinal joints are normally designed at a regular spacing e.g. 4.5m to accommodate the effect of differential settlement of pavement foundation. When uneven settlement occurs, the tie bars in longitudinal joints perform as hinges (Ministry of Transport (1955)) which allow for the settlement of concrete carriageway. Moreover, it also serves to cater for the effect of warping of concrete due to moisture and temperature gradients by permission of a small amount of angular movement to occur so that stresses induced by restrained warping can be avoided.

Dowel bars are provided in longitudinal joints for the following reasons:

(i) In case of the occurrence of uneven settlement between adjacent panels, it helps to maintain a level surface by transfer of loads through dowel bars.

(ii) Keep the longitudinal joints close.

11. For rigid pavement, what are the advantages of using lean concrete sub-base instead of traditional granular sub-base?

There are several shortcomings of using granular sub-base in concrete carriageway:

(i) Since sub-base is permeable, water can seep through sub-base and soil particles will be pumped out through contraction/expansion joints when subject to traffic load. Consequently, voids are formed underneath the pavement structure and the concrete pavement may crack under severe traffic loading.

(ii) Lean concrete increases the strength and renders the roads capable of carrying heavy traffic loads (David Croney and Paul Croney (1992)).

(iii) Due to workmanship problem, it may have uneven distribution of sub-base and this results in cracking of concrete carriageway when subject to severe traffic loading.

12. In General Specification for Civil Engineering Works (1992 Edition), the design of roadbase material is based on recipe approach. Why?

The design of roadbase material is based on recipe approach (David Croney and Paul Croney (1992)) because Hong Kong government follows the traditional British practice by adopting recipe design in which the aggregate grading envelope, the quantity and grade of bitumen are specified in the bituminous mix. This recipe of bituminous mix is derived based on past experience and good workmanship during construction. In fact, many countries nowadays adopt special design mix of roadbase which proves to produce satisfactory bituminous mixes to suit different site and design conditions.

In fact, recipe specification of bituminous materials does suffer from several drawbacks. Firstly, the conditions of traffic and climate of newly constructed bituminous road may differ from the conditions on which the recipe design is based. In case adjustment has to be made to the recipe design, it is very difficult to determine and assess the modifications required. Secondly, it poses problem to site engineers to assess the effects of minor non-compliance if recipe specification is adopted. Finally, the recipe mix may not be the most economical design which is dependent on site conditions.

13. If the construction of concrete carriageway is carried out in summer,can expansion joints be omitted?

If the construction of concrete carriageway is carried out in summer, expansion joints may not be necessary as suggested by Arthur Wignall, Peter S. Kendrick and Roy Ancil. Expansion of concrete carriageway is mainly due to seasonal changes with an increase in temperature from that during construction to the ambient temperature (i.e. the temperature in summer). However, if the construction of concrete carriageway takes place in summer, the concrete carriageway will undergo contraction in the following winter, thus the space available in contraction joints can accommodate the future expansion in the next summer.

14. If there is a delay of bituminous laying on top of sub-base, should tack coat be applied on the top surface of sub-base?

When there is a delay between bituminous laying of different bituminous layers (i.e. roadbase, base course etc.), a tack coat is applied on top of the bituminous layers because it helps to enhance better bonding between bituminous materials. If there is insufficient bonding between adjacent bituminous layers, they behave as separate independent layers which can hardly resist the traffic loads. When applying the tack coat, it should be sprayed uniformly on the bituminous surface and allowed for sufficient curing. The hot bituminous material laid on top of the coat would soften it, enabling the tack coat to partly fill voids in the bituminous materials. For emulsified asphalt type tack coats, they are normally diluted with water in order to achieve a more uniform application without excessive usage of asphalt. After the subsequent compaction is carried out, the coat would be interlocked with the bituminous materials. On the other hand, care should be taken to ensure that excessive coat would not be laid, otherwise slippage or shear cracks in the bituminous material would occur due to the relative thick layer of the tack coat applied.

However, for sub-base surface, priming coat instead of tack coat may be applied in the event of a delay in laying of bituminous layer on top of the sub-base layer. The function of the primer serves to maintain the existing surface condition for a longer period and it also provides an impermeable surface to prevent ingress of water or water loss by evaporation. Moreover, it fills the surface voids and protects the sub-base from adverse weather conditions. In addition, it also helps to promote adhesion between adjacent road layers and to harden the surface.

15. What is difference in purpose for conducting surface regularity test and sand patch test (test on texture depth)?

The purpose of surface regularity test is to measure the riding quality of pavements and the same requirement and standard is applied to both concrete and bituminous carriageway. On the other hand, sand patch test is used for checking the skid resistance of road pavements. Moreover, it is related to traffic noise because the intensity of noise generated from road traffic is related to texture depth of carriageway.

16. In General Specification for Civil Engineering Works (1992 Edition), it specifies the temperature requirements for bituminous material during and after mixing. What is the reason behind this?

Temperature is one of the factors that govern the compaction of bituminous material and the air void content is found to decrease with an increase in compaction temperature. This phenomenon is explained by the viscosity-temperature relations: the higher is the viscosity of binders, the greater is the resistance to compaction. Therefore, in normal contract for bituminous laying, the temperature requirements for bituminous material during and after mixing are specified.

17. Can a sub-base layer serve as a drainage layer to remove water from pavement?

Besides providing load distribution in post-construction stage and working platform in construction stage, sub-base can also serve as a drainage layer to remove water coming from the pavement. For thick layers of road pavement, it is likely that the water leakage from pavement is insignificant and therefore the sub-base layer mainly serves to support the traffic stresses. However, for thin pavement layers, water penetration is quite substantial and therefore sub-base may also act as a drainage layer to remove these water.

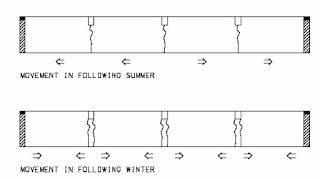

18. For unreinforced concrete carriageway, what is the sequence of closing and opening of expansion joints and contraction joints?

Let’s take an example to illustrate the sequence of closing and opening of joints (Ministry of Transport (1955)). For instance, an unreinforced concrete carriageway is constructed in winter. When temperature rises in the following summer, the section between expansion joints will expand as a whole single element resulting in the closure of expansion joints. This section of concrete pavement will move outwards from the mid-point between the expansion joints. In the next winter, each bay (i.e. concrete pavement between adjacent contraction joints) of concrete contracts about the midpoint of its length with opening of contraction joints.

|

| Movement of joints in summer and winter |

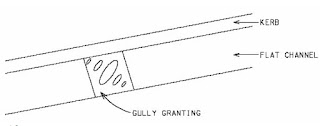

|

| kerbs are essential in road pavements |

No comments:

Post a Comment

If you are getting more information from civilengineerfriend page please give your comments. Share the page information in your whatsapp group. Subscribe our page to get more information.