1. What is the difference among cement plaster, cement render and cement screed? Under what situations should each of the above be used?

The purpose of plastering, rendering and screeding is to create a smooth, flat surface to receive finishes like paint, wallpaper etc.

Plastering is the intermediately coating of building materials to be applied on the internal facade of concrete walls or blockwalls. Rendering is the intermediate coating for external walls only. Screeding is the coating laid on floors to receive finishes like tiles, carpet, and marble...

Hence, these terms differ basically from the locations at which they are applied. Due to different locations of application of plasterwork, the proportion of material component for plaster and render is different. For example:

(i) Cement plaster

Undercoat- cement:lime:sand (by volume) = 1:4:16

Finishing coat - cement:lime:sand = 1:12:30

(ii) Cement render

Undercoat- cement:lime:sand (by volume) = 1:2:6

Finishing coat - cement:lime:sand = 1:3:6

2. In the design of corbel beams in a pumping station, why are shear links designed in the top 2/3 of the section? What is the general advice on the design?

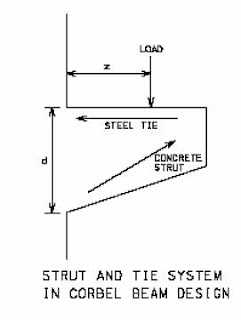

Corbel beams are defined as z/d<0.6 where z is the distance of bearing load to the beams’ fixed end (or called shear span) and d is depth of beams. The design philosophy is based on strut and tie system. To establish the design model, it is firstly assumed the failure surface, i.e. shear cracks extending to 2/3 of depth of beam. Experiment results verified that the failure cracks extended only to 2/3 of beam while the remaining 1/3 depth of concrete contributed as concrete strut to provide compressive strut force to the bearing loading.

Horizontal links are normally provided to corbel beams because experimental results indicated that horizontal links were more effective than vertical links when shear span/depth is less than 0.6. For shear span/depth>0.6, it should be not considered as corbel beams but as cantilevers.

In designing corbel beams, care should be taken to avoid bearing load to extend beyond the straight portion of tie bars, otherwise the corners of corbel beams are likely to shear off. Reference is made to L. A. Clark (1983).

|

| the design of corbel beams |

3. Given a 1m high staircase resting on solid concrete, would it be adequate to design nominal reinforcement for the staircase?

For the design of staircase, there are three main scenarios:

(i) Stairs spans longitudinally

This kind of stairs refers to stairs spanning between landings only without any side supports. In this case, the staircase should be designed as a beam between two end supports (i.e. landing) and the main reinforcement is provided at the bottom of staircase slabs.

(ii) Stairs spanning transversely

This kind of staircase is supported by sidewalls only and it may also be supported by stringer beams. For the case of sidewalls, it acts as a cantilever beam and the main reinforcement are provided the top surface of slab. For the case of staircase supported sideways by both sidewall and stringer beam, it should be designed transversely with end supports as sidewall and stringer beam and reinforcement is provided at the bottom of the staircase.

(iii) Stairs resting on solid support

For stairs resting on solid supports, only nominal steel reinforcement is provided to control thermal and shrinkage cracking.

4. In selecting screw pumps in polder scheme projects, what are the factors that affect the design capacity of screw pumps?

The commonly used angles of inclination for screw pumps are 30o, 35o and 38o. For screw pumps of relatively high lifting head, like over 6.5m, angle of inclination of 38o is normally used. However, for relatively lower head and high discharge requirement, angle of inclination of 30o shall be selected. In general, for a given capacity and lifting head, the screw pump diameter is smaller and its length is longer for a screw pump of 30o inclination when compared with a screw pump of 38o inclination.

To increase the discharge capacity of screw pumps, a larger number of flights should be selected. In fact, screw pumps with 2 flights are more economical that that with 3 flights in terms of efficiency and manufacturing cost. Moreover, the discharge capacity is also determined by the screw pump diameter and size of 300mm to 500mm are available in current market

5. What are the components of a waterproofing system in the roof of a typical pumping station?

In the design of a waterproofing system at the roof of a pumping station, normally the following components are:

(i) Above the structural finish level of the concrete roof, a screed of uniform thickness is applied to provide a smooth surface for the application of waterproofing membrane. (Screed of varying thickness can also be designed on the roof to create a slope for drainage.) The screed used for providing a surface for membrane should be thin and possess good adhesion to the substrate. Moreover, the screed aids in the thermal insulation of the roof.

(ii) Above the screed, waterproofing membrane is provided to ensure watertightness of the roof.

(iii) An insulation board may be placed on top of waterproof membrane for thermal insulation. In cold weather condition where the loss of heat at the roof is significant, the insulation board helps to reduce these losses. On the contrary, in summer the roofm is heated up by direct sunlight and the insulation layer reduces the temperature rise inside the pumping station.

6. In pumping stations one of the choices for the material of water tanks is fibre-reinforced plastic (FRP). What are the advantages associated with this kind of material?

There are two main advantages for FRP water tanks:

(i) It possesses high strength to weight ratio and this leads to the ease of site handling.

(ii) It is highly resistant to corrosion and thus it is more durable than steel water tank.

7. In the construction of pump troughs for accommodation of screw pumps, what is the construction method to ensure close contact between the screw pumps and the pump trough?

In the construction of screw pump troughs, trapezoidal-shaped troughs are usually formed by using normal formwork. In order to enhance close contact between screw pumps and troughs, upon lifting the screw pumps into the troughs screeding works is carried out. Screw pumps are set to rotate and screeds are placed between the gap of screw pumps’ blade and trapezoidal-shaped troughs during the rotating action of screw pumps. After the screed sets, it serves to prevent leakage of water during the pumping operation of screw pumps.

8. Why are voids filled with lightweight infilling material in raft foundation of pumping stations?

To reduce the dead load and hence to reduce the settlement of pumping stations, the voids inside the raft foundations are filled with light material. If instead concrete is placed inside these voids, it poses severe thermal cracking problem and drastically increases loads to pumping stations. The use of general fill is also not desirable because its self-weight is comparable to that of concrete. On the contrary, if these voids are left vacant, water may penetrate into these voids during future operation and increases the dead load of pumping stations during its normal operation. Therefore, lightweight infill material, which is non-water-absorbing and non-biodegradable, is designed inside these voids to avoid ingress of water and to reduce the dead load of the structure.

9. What is the difference in arranging pumps in series and in parallel?

For identical pumps with similar functions, if the pumps arranged in series, the total head is increased without a change to maximum discharge. On the other hand, for pumps arranged in parallel to one another, the discharge is increased without any changes to maximum head.

10. In terms of pumping performance, how should engineers determine the use of radial flow pumps and axial flow pumps?

Specific speed is usually defined for a pump operating at its maximum efficiency. In order to minimize the cost of future operation, it is desirable to operate the pumps as close to the maximum efficiency point as possible. The specific speed for radial flow pumps is relatively small when compared with that of axial flow pumps. This implies that radial flow pumps tend to give higher head with lower discharge while axial flow pumps tend to give higher discharge with lower head.

No comments:

Post a Comment

If you are getting more information from civilengineerfriend page please give your comments. Share the page information in your whatsapp group. Subscribe our page to get more information.