DMC piling method procedure

Direct Mud Circulation method of pile foundation installation is used for bored cast in-situ piles. Direct Mud Circulation method is best suited when working-space is a huge constraint. In Industries and power plants where there is a labyrinth of pipelines snaking all around, DMC comes to the rescue.The whole project report is subdivided in the following

sections:

1. Introduction

2. Objectives and classification of piles and piling

methods

3. Principle of DMC piling

4. Apparatus used

5. Field procedure DMC piling

6. Conclusion

1. INTRODUCTION

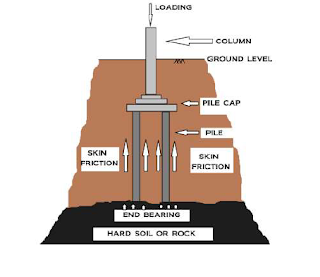

Piles are the columnar structure, the most common type of

deep foundation, that safely transfer loads from the super

structure to more competent subsurface strata by means of

friction, end bearing or a combination of both. Piles can be

broadly classified based on the following parameters.

1. Method of installation of piles – Driven (displacement) piles

or bored (replacement) piles.

2. Type of material used for piling – Concrete, steel, timber

piles etc.

Among these, concrete piles can be classified further as precast

and cast in situ concrete piles. Though there are a variety

of piling options, the most common type of piles used for

majority of construction works in India are bored cast in situ

concrete piles.

2. Objectives and classification of piles and piling methods Functions of piles:

The major uses of piles are:

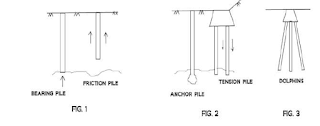

1. To carry vertical compression load, eg. bearing piles,

friction pile. (FIG. 1)

2. To resist uplift pressure, eg. tension piles or uplift piles or

anchor piles. (FIG. 2)

3. To resist horizontal or inclined loads, eg. Batter piles.

(FIG. 3)

Setting up piles

Depending up on the setting up principle, piles can be of two types, eg. Displacement type and Replacement type, each has its own advantages and disadvantages. For displacement piling

method, piles are driven into the ground pushing the soil out of its way. Displacement piling is good for contaminated sites where it costs a lot to move the soil out.

Using the replacement piling method, muck is dug out and replaced with the pile. Much bigger piles can be casted by replacement method.

Direct Mud Circulation (DMC) piling method or simply DMC Piling method is an example of replacement piling method. This method is the principle subject of interest in this report.

The advantages of displacement piling are:-

Self testing as driven to refusal or "set"

No pile arising to dispose of

Little disturbance

Limited access

High production

The disadvantages of displacement piling are:-

Cannot penetrate obstructions

Cannot always penetrate desiccated clay

Vibration and noise may be an issue

The advantages of replacement piling are:-

Effectively vibration free

Installed into non cohesive and water bearing soils

High production

Restricted access

The main disadvantage of replacement piling is that:-

it produces excavated material which requires removal off site

3. Principle of DMC piling

DMC piling is a typical wash bored piling method, ie. the piles are of REPLACEMENT type. For this type of piling method, the sub soil must be of cohesive nature. The basic principle of DMC piling

lies in the fact that the soil layers becomes harder to penetrate with depth, so to soften the hard soil layers deep below the ground level,water jet streams are used and then a typical chisel cuts the

relatively softer soil. Bore holes of several depths (for example 10m,15m, 20m, 25m, 30m, etc.) and diameter (for example 500mm 750mm, 1000mm etc.) are dug as per design requirements. It can be

understood quite clearly that the nearby soil can collapse. To prevent the collapse some special safety measures are considered during the operation which will be discussed in later sections. After the bore hole is dug and the collapse of subsoil around the hole is safely prohibited, a reinforcement cage is entered into the borehole and concrete is filled from the bottom of the hole with the help of pipes, typically designed for this operation, called the Tremie pipes. Usually concrete is left 28 days to harden and gain full strength, but sometimes using admixtures they are prepared within 21 days.

4. Apparatus used

I. DMC rig

THE TRIPOD SYSTEM

Main shear leg: it is the longer leg than the other two that carries the load.

The length is 7.5m. The length can be adjusted. With the help of 20mm dia pins

The side shear legs: there are two side shear legs, 6.3m long

and they mainly support the tripod system.

The side legs must be placed at least 1.5m away from the centre

of the piles.

BASE CHANNEL

These are standard I section, 2cm thick and there are grooving in it that holds the shear legs onto the ground with the help of base cannel pin.

•

SLIP OVER WHEEL

Diameter

|

450mm

|

Thickness

|

50mm

|

Operation

|

The rope slips over this

wheel or Pulley

|

| ||||||

• S.O. WHEEL

PIN

SLIP OVER WHEEL • SLIP OVER WEEL HOLDER

Diameter = 500 • PLUNGE

Inside Diameter = 50mm

• SUSPENSION

PLATE – this is called into action if somehow the chisel is stuck in the

borehole. Pulleys are attached here and the chisel is pulled out.

|

Suspension Plate

• MAIN SHEAR

LEG PIN – 20mm dia.

II. Winch

Capacity

|

3 Ton (Other

capacities can be of

1 Ton 2.5

Ton 5 Ton 7.5 Ton etc.)

|

Driven wheel diameter

|

900mm

|

II. Diesel engine • USED IN

WINCH (RUSTON MAKE)

Number of cylinder

|

4

|

3

|

Diesel consumption

|

2.1 lit/hr

|

1.75 lit/hr

|

Mobil

consumption (fresh engine)

|

0.5 lit per 7 days

|

0.5 lit per

7 days

|

Mobil

consumption (older engine)

|

0.5 lit per 12 hours

|

0.5 lit per

12 hours

|

• USED IN

PUMP (KILOSKER MAKE)

Number of cylinder

|

2

|

Diesel consumption

|

1.25 lit/hr

|

Mobil consumption

|

250ml per 12

hours

|

IV. Bailer or Slush Pump

Length

2700mm

|

Inside

Diameter

450mm

|

Weight

0.5 Ton

|

V. Guide casing

Length

2750mm

|

Inside

Diameter

550mm

|

Thickness of

casing

30mm

|

Thickness of

collar

20mm

|

Thickness of

sheet

80mm

|

Inside

Diameter

400mm

|

Length

2500mm

|

Number of

nozzle

4

|

7. DMC rod

Length (m)

|

2.7 3 3.25

|

Diameter (mm)

|

95 75 65

|

Thread length (mm)

|

120

|

Thread type

|

Tapered

|

ID of tapered king end

(mm)

|

80

|

ID of queen end (mm)

|

120

|

Tapered thread

end of DMC rods

7.

Rope

Diameter – 20mm

8.

Tremie pipe

ID

|

5 inch

|

OD

|

6 inch

|

Thickness of sheet

|

12mm

|

9.

Vertical

pump

Power source

|

Electrically

operated

|

Power

|

10 Hp

|

10.

Bentonite

tank and Bentonite slurry

The Bentonite tank stores the Bentonite water which is

of avg. Density of 1.04gm/cc. The minimum density is 1.03gm/cc and maximum

density is 1.05gm/cc

Vertical Pump in Bentonite tank

7.

Wash vat

This is where the muck mix with water gets stored, the

muck gets precipitated and the water becomes reusable.

8.

Tremie fork

Used

to insert the tremie pipes and taking out DMC rods.

5.

Field

procedure DMC piling

• For

executing DMC piling method which is approved as per IS 2911 under

specifications of bored cast in situ piles. The positioning of points where the

piles are proposed to set up, are checked by the surveyor.

Ø DMC piling Rig set-up and initiation of boring

using the Bailer

• After

the point for boring operation is set out by the surveyor the tripod is paced

such that each side legs are at least 1.5m away from the point, keeping the

centre of borehole exactly in the centre.

• The

bailer is then attached with the rope and the boring operation is initiated.

• After

bailer reaches its full length into the soil, the guide casing is inserted into

the hole for farther operations.

Insertion of the guide casing

To

prevent the side collapse and caving in, a guide casing of 550mm dia and of

2750mm length is placed on the top of the bore hole and hammered by the bailer

to insert it into the soil. This will be withdrawn after concreting is over.

Ø Boring with Chisel

• Once

the guide casing is placed, the boring is started with chisel.

• The

chisel has 4 nozzles from where water jet is forced on the hard soil layer as

the boring progresses.

Ø

Progression of boring and addition of DMC rods

• DMC

rods are added one after another as the depth increases.

• The

DMC head are attached on top of the DMC rods which has the plunge which

receives the water from delivery hose.

• The

whole system is pulled up by the rope and the D-Shackle with the help of the

winch system and then left to fall free, so that the chisel at the bottom cuts

the soil and the boring progresses.

• The

loose soil produced by boring, mixes with water and comes up and is stored in

the wash vat, where the soil gets precipitated and the water is again

usable.

Ø

Taking out of the DMC rods and Chisel and Insertion of the reinforcement

cage

• After

the boring is complete up to the desired depth, the DMC rods are removed one by

one using the DMC fork and the chisel is also removed.

• Then

the steel reinforcement cage is inserted and welded where ever there are

joints.

Ø

Concreting

and finalization of the process

• The tremie

pipes are inserted one by one using the Tremie fork and then the bore hole is

washed with the Bentonite water and the Muck is completely removed and the hole

is filled with bentonite slurry.

• The Transit

mixer arrives and the Hopper is attached on top of the tremie pipe.

• The TM puts

concrete mix into the hopper and the valve opens. The bore hole is gradually

filled with concrete which is

compacted by gradual vibration of tremie pipes. This

filling of concrete from the bottom is done to avoid segregation of the

concrete mix.

• As the

concrete fills the hole from bottom, Bentonite slurry escapes the hole. The

tremie pipes are detached one by one and thus the hole gets filled completely.

• After the

hole is fully filled, the concrete is left 28 days to gain full strength. After

28 days the guide casing is removed and the pile is ready.

6. Conclusion

DMC

piling is the most common piling methods used in India. For moderate sized

piles, that is 450mm to 1000mm diameter and 25m to 30m depth piles; it is also

most convenient and economic way of piling. Larger piles that are of diameter

up to 1500mm can also be founded by this method, but those are not that convenient.

Other process like Reduced Mud Circulation (RMC) is also in use.

No comments:

Post a Comment

If you are getting more information from civilengineerfriend page please give your comments. Share the page information in your whatsapp group. Subscribe our page to get more information.