Post Tension Slab – Working Principle, Components and Construction

Post tension slab is a combination of conventional slab reinforcement and additional protruding high-strength steel tendons, which are consequently subjected to tension after the concrete has set. This hybridisation helps achieve the formation of a much thinner slab with a longer span devoid of any column-free spaces.

In this article we study about the working principle, components, construction and advantages of post tension slab.

What is Post-Tensioning

Post tensioning is a technique for reinforcing concrete. Post-tensioning tendons, which are prestressing steel cables inside plastic ducts or sleeves, are positioned in the forms before the concrete is placed. Afterwards, once the concrete has gained strength but before the service loads are applied, the cables are pulled tight, or tensioned, and anchored against the outer edges of the concrete.

Post-tensioning is a form of prestressing. Prestressing simply means that the steel is stressed (pulled or tensioned) before the concrete has to support the service loads. Most precast, prestressed concrete is actually pre-tensioned-the steel is pulled before the concrete is poured. Post-tensioned concrete means that the concrete is poured and then the tension is applied-but it is still stressed before the loads are applied so it is still prestressed.

Working Principle of Post Tensioning

We all know that concrete has a high compressive strength and steel has a high tensile strength, and when their combination is used to bear loads, the efficiency increases manifold.

|

| Typical Details of Post Tension Slab |

When a heavy live load is brought upon a structure, its concrete slab undergoes tension, which leads to the formation of cracks and ultimately deformation occurs. To mitigate this problem, post tensioned steel tendons are inserted at the time of concreting and tensioned after concreting with conventional rebars.

When these post tensioned steel tendons are stressed, the concrete is squeezed, in other terms, the concrete is compacted which increases the compressive strength of the concrete and at the same time the steel tendons that are pulled increase the tensile strength. As a result, the overall strength of the concrete increases.

Components of Post Tensioning Slab

1. Ducts

Thin sheet metal pipes with claw coupling or welded overlapped seam supplied in lengths of 5 and 6 m respectively are used as a standard. Ducts are connected to each other by an external screw coupling and sealed with PE tape. Plastic ducts are also available in the market these days which are water tight , frictionless and fatigue resistant

|

| Type of Ducts used to encase steel tendons |

2. Tendons

The basic element of a post-tensioning system is called a tendon. A post-tensioning tendon is made up of one or more pieces of prestressing steel, coated with a protective coating, and housed inside a duct or sheathing.

|

| Steel tendons used in Post Tensioning of Slab. |

The prestressing steel is manufactured as per the requirements of ASTM A-416 and typical strand sizes are 0.50 and 0.60 inch in diameter. A typical steel strand used for post-tensioning will yield about 243,000 psi. In contrast, a typical piece of rebar will yield about 60,000 psi.

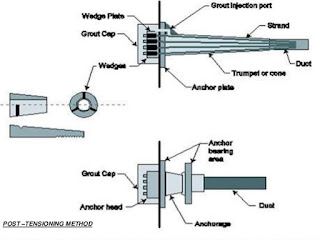

3. Anchors

Anchors are used to anchor the tendons into the concrete while terminating or joining two tendons. Main function of anchorage is to transfer the stressing force to the concrete once the stressing process is completed.

|

| Slab Anchor. |

Construction of Post Tensioned Slab

- The installation of post tensioning tendons in the concrete and stressing it requires skilled labour and a personnel who are certified in doing the tensioning works.

- The tendons are laid down along with the conventional rebars. The position of laying of the tendons is decided by the engineer. These tendons are encased in plastic or steel ducts so that they do not come in contact with the water in concrete.

- One end of the tendons are anchored with the help of anchor and the other end is left open with plastic pocket former, where the tendons are stressed. Couplers are used in between if any construction joint is formed.

- Concrete is poured and the alignment of these tendons are taken care of so as to let their positions unaltered. Once after the concrete has achieved its 75% of strength , that is around 20 – 23 days, these tendons are stressed with the help of stressing jacks.

- The tensioning is done to a force equal to 80% of a strand’s tensile strength. For a typical ½-inch grade 270 strand, the strand is tensioned to a force of 33,000 pounds. As the tensioning comes into effect, the steel gets elongated, and the concrete is compressed.

- When the proper tensioning force is reached, the prestressing steel is anchored in place. The anchors are designed to provide a permanent mechanical connection, keeping the steel in tension, and the concrete in compression.

- The extra tendons that are left out at one end are trimmed and non shrink grouting is put in the anchor pocket.

- Construction of concrete slabs on the ground in areas where the soil is more likely to move.

- Strengthening of existing structures that are susceptible to seismic shifts.

- Precast concrete segment construction in bridges to allow for longer spans.

- Preventing cracks and leakage in concrete water tanks.

- Substantial material savings: Post-tensioning enables the use of thinner concrete members, which can reduce overall concrete requirements by as much as 20 percent. Additionally, the rebar in floor elements can be reduced by as much as 75 percent.

- Faster construction times: You can also experience quicker construction times thanks to faster pouring cycles, fewer re-shoring requirements and improved coordination with imbeds and MED openings. Faster construction time usually translates to faster overall project completion times.

- Improved performance: Post-tensioning concrete usually provides better performance in areas such as improved seismic behavior, less vibration and deflection, enhanced crack control and waterproofing, and greater flexibility in floor layouts.

- Lower long-term costs: You can experience lower costs over the long haul in the form of less maintenance requirements, reduced building heights that can provide significant energy savings, along with the opportunity to earn LEED credits.

Advantages of Post Tension Slab

1. Architectural Benefits

Post-Tensioned Slab has an advantage over others as it makes a very efficient base for floor design with thin slabs and columnless spaces in larger spans. It provides an architect the freedom to work freely with his designs.

2. Commercial Spaces

Post-tensioning results in thinner concrete slabs making the valuable savings in floor to floor height available as additional floors.This can provide extra rentable space within the same overall building height.

3. Reduces Deadload

As the post-tensioned slabs have lesser thickness, the quantity of concrete and reinforcement used is reduced upto 20% – 30% when compared to conventional concrete slabs.

4. Structural Durability

Post-Tensioned slabs show reduced cracking, improved durability and lower maintenance costs. Their deflection can be controlled by varying the amount of post-tensioning to balance any portion of applied loads immediately after stressing.

5. Popularity

The demand for Post-Tensioned slabs, throughout the world, continues to increase because of the significant benefits for developers, architects, engineers, contractors and end users.

Post-Tensioned Prestressed Concrete

As a building material, concrete is strong in compression, but weak in tension. Reinforcement helps extend the life of concrete, overcoming cracking that is inherent in the material and preventing its failure. Reinforcement has been used in concrete since mid-19th century France, when iron was first embedded in concrete planters. Its use quickly spread to bridges, buildings, and other civil and commercial applications. The fact that concrete is one of the most consumed COMMODITIES on the planet owes in part to the improved performance characteristics obtained through reinforcement.

As a building material, concrete is strong in compression, but weak in tension. Reinforcement helps extend the life of concrete, overcoming cracking that is inherent in the material and preventing its failure. Reinforcement has been used in concrete since mid-19th century France, when iron was first embedded in concrete planters. Its use quickly spread to bridges, buildings, and other civil and commercial applications. The fact that concrete is one of the most consumed COMMODITIES on the planet owes in part to the improved performance characteristics obtained through reinforcement.

Post-Tensioning Concrete Is a Method of Active Reinforcement

Post-tensioning concrete with steel strand became a popular solution to deflection and weight in slabs in the US in the 1950s. Post-tensioning is an efficient method of concrete reinforcing that reduces mass while improving building stability and resistance to wind, gravity, and seismic forces. Used in both precast and cast in place concrete construction, post-tensioning is considered active reinforcement because it applies tension to the concrete. This distinguishes post-tension concrete from passive reinforcement, which is accomplished by rebar and mesh embedded in the post-tensoned concrete.

Prestressed vs. Post-Tensioned Concrete

Post-tensioning and pretension prestressing are similar concepts. In post-tension concrete, steel strands or cables pass through the concrete member in plastic ducts or sleeves. After the concrete has gained strength, but before the service load is applied, the strand is pulled tight and then anchored against the outside of the concrete member. The strand used for post-tensioning and pretensioning concrete is the same, and can be used with or without a sleeve depending on design. Corrosion-resistance and strand lubrication is achieved with grease.

Post-Tension Concrete Can Increase Strength and Prevent Cracking

Depending on design, post-tensioning concrete can strengthen it to support loading as well as control plastic shrinkage cracking while using less reinforcement and concrete material than passive reinforcement systems. Any cracks that do form will be tightly held together, minimizing the possibility of propagation. Post-tensioning can also allow for longer concrete members, and can also reduce the volume of concrete so that panels, double tees, and other members can be thinner and lighter in weight.

In What Types of Structures Is Concrete Post-Tensioned?

Prestressed and post-tensioned concrete are often used together in the construction of wall panels and parking decks. Here’s how both processes are combined:

In wall panels, vertical post-tensioning strands pass from the top of the wall to the base of the structure through plastic sleeves cast into the panel. Prestressed strand is then fed through the sleeves and then post-tensioned. Studies have shown this to be an effective way to increase structural stability, at a cost that is typically lower than conventional reinforcement methods.

In parking decks, post-tensioning can be used in combination with prestressing to provide effective lateral reinforcement. This is a desirable construction technique for designers who choose to do away with field-applied pour strips that bring the potential for corrosion of diaphragm reinforcing steel.

Post-tensioned lateral reinforcement is particularly useful in applications calling for double tees of 15’ to 16’ widths or greater. The flange portions of adjacent prestressed double tee beams may be transversely post-tensioned together, replacing traditional methods used to resist lateral loads. Pour strips and cast-in reinforcing can be eliminated, reducing costs, improving concrete quality, and shortening field erection schedules.

Other Post-Tensioning Concrete Applications

Additional applications of post-tensioned concrete include:

Summary of Post-Tension Concrete Benefits

Post-tensioning concrete offers:

No comments:

Post a Comment

If you are getting more information from civilengineerfriend page please give your comments. Share the page information in your whatsapp group. Subscribe our page to get more information.